Company Profile

Dongguan Mixiao Technology & Hong Kong Hansheng Industrial Co., Ltd was established in 2013. It’s an industrial and trade integrated enterprise which focusing on cemented carbide.

MiXiao Tech mainly supplies cemented high-quality carbide,such as carbide plate and rod, Special carbide products, Carbide for mining, Roll rings, Cutting inserts, Moulds and dies, Steel-bonded carbide, Engineering tools, Mining tools, Cast tungsten carbide, Spray powder, Copper based welding rods, Tungsten & molybdenum powder, Carbide grade powder, Cobalt and its compounds, Tungsten compounds, Molybdenum compounds, Tungsten products, Molybdenum compounds, Tantalum products and any other high-quality beryllium copper, titanium copper and copper alloy materials with high conductivity for precision connector and electrical industry.

Our products are widely used in the industries of metallurgy, machinery, mining, petroleum-chemistry, electronics,cars, textile and furniture. Our company have established long-term and in-depth cooperation with NGK,DOWA,JX and other well-known metal material suppliers. At the same time, we also maintain long-term good cooperative relations with well- known copper alloy manufacturers in China. The company has strong financial strength, common specifications to ensure adequate supply of goods, most of the spot supply, flexible delivery quantity, saving delivery time. We always adhere to the reliable quality based on the market, with reasonable price to win long-term cooperation with customers, mutual benefit and create value. Welcomes all customers from all over the world to visit us.

Business Description

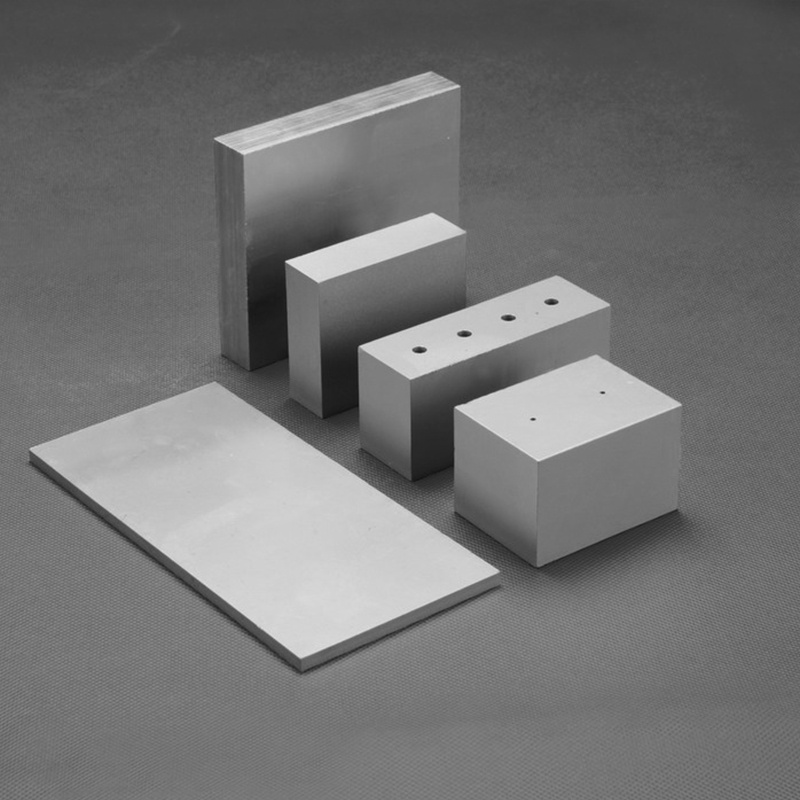

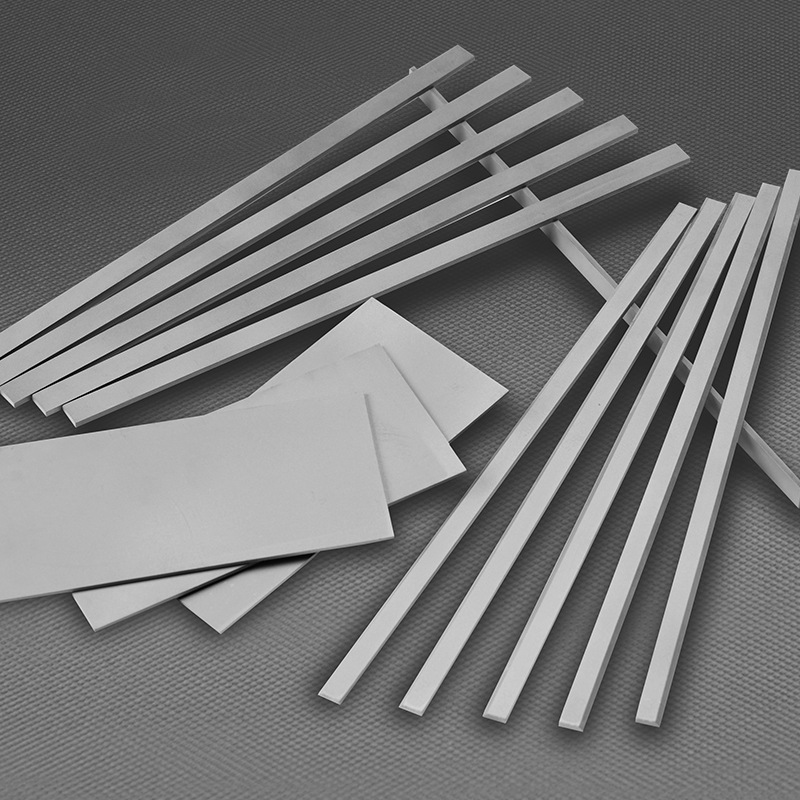

M&A Cemented Carbide

We are constantly developing new carbide materials in a wide range of fields, such as wear resistant tools and metal molds.

M&A cemented carbide utilizes the hardness and strength to create drills, milling cutters, bites, and other cutting tools for metal processing. It is also used in metal molds for aluminum drink cans, powder molding molds for automobile engine parts, metal molds for electronics, and more. We strive for detailed research and development that meets the needs of our customers in order to provide the best cemented carbide.

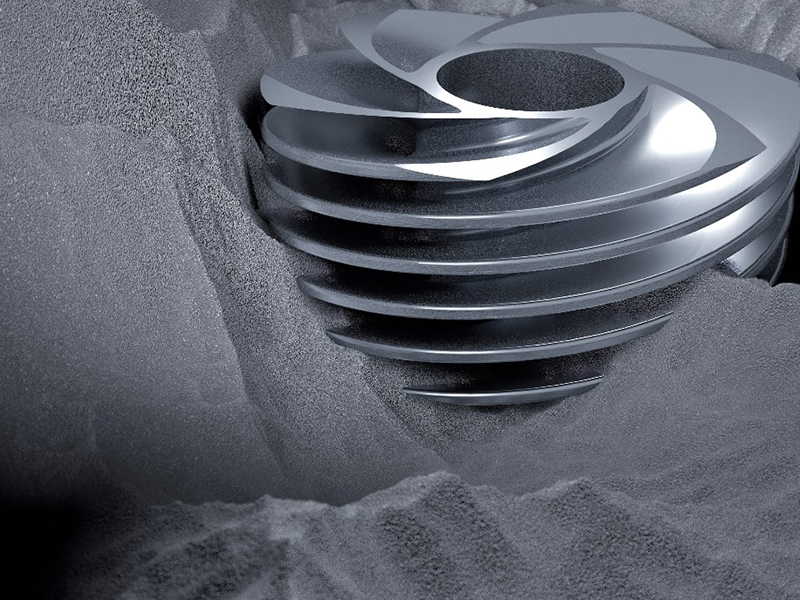

M&A Precision Machining

M&A's precision machining has achieved great results in a wide variety of fields, including the metal mold industry and the need for submicron precision.

M&A's precision machining has proven results in a wide variety of fields, including the semiconductor industry, motor industry, automobile part industry, and the metal mold industry where submicron accuracy is required for inspection systems or equipment that realizes high precision processing. We are constantly concentrating on new knowledge and technology, and we offer high quality products that our customers can use safely.

Versatility and performance are the hard metal’s trump cards

Whether car, aeroplane, wind turbine, tunnel, smartphone, diaper or glass bottle – every day we come into contact with large and small things, in the manufacture or construction of which cemented tungsten carbide (hereafter simply called tungsten carbide, after its main constituent) plays an important role.

Most people are unaware of this, but industry and professional users value the advantages of tungsten carbides. Whenever tools and components are exposed to extreme loads, the use of tungsten carbide is an obvious choice. The high hardness, wear resistance and toughness in combination with its many other high-performance properties that can be adjusted over a wide range make tungsten carbide the ideal material for a multitude of applications.

Currently, far more than one hundred different carbide grades are available to optimally address the requirements of a wide variety of applications. And the development of tungsten carbide has not yet ceased, as new challenges for tools and components as well as the opening of new fields of application always offer room for further improvements.

What is tungsten carbide?

But what is tungsten carbide? Tungsten carbide (also often referred to as ‘hard metal’) is a composite material fabricated by powder metallurgy, which consists of one or more hard material phases (e.g. tungsten carbide itself, hereafter referred to as WC) and a binder metal surrounding the hard material grains (e.g. cobalt, Co or nickel, Ni).

As with all hard metals, the hard WC phase gives the tungsten carbide its high hardness, hot hardness and wear resistance, while the binder metal ensures good toughness of the material. With an extremely high Young's modulus, carbide hardly deforms plastically during stress. This combination of properties alone makes tungsten carbides interesting for a variety of applications. However, the enormous versatility stems from the fact that the properties can be varied over a wide range of scales, which is why tungsten carbides can be used in very diverse areas of application - with high impact or bending loads as well as with high wear loads.

By far the most frequently used hard metals are those based on WC and Co, the tungsten carbide hard metals. They are not only used in metal cutting (ISO application group K), but also in products for wood and stone working as well as for many wear parts.

In addition to the simple WC-Co carbides, there are also those with mixed carbides which also contain titanium, tantalum or niobium carbides in addition to WC. They are used for steel cutting (ISO application group P) as well as for metal saws.