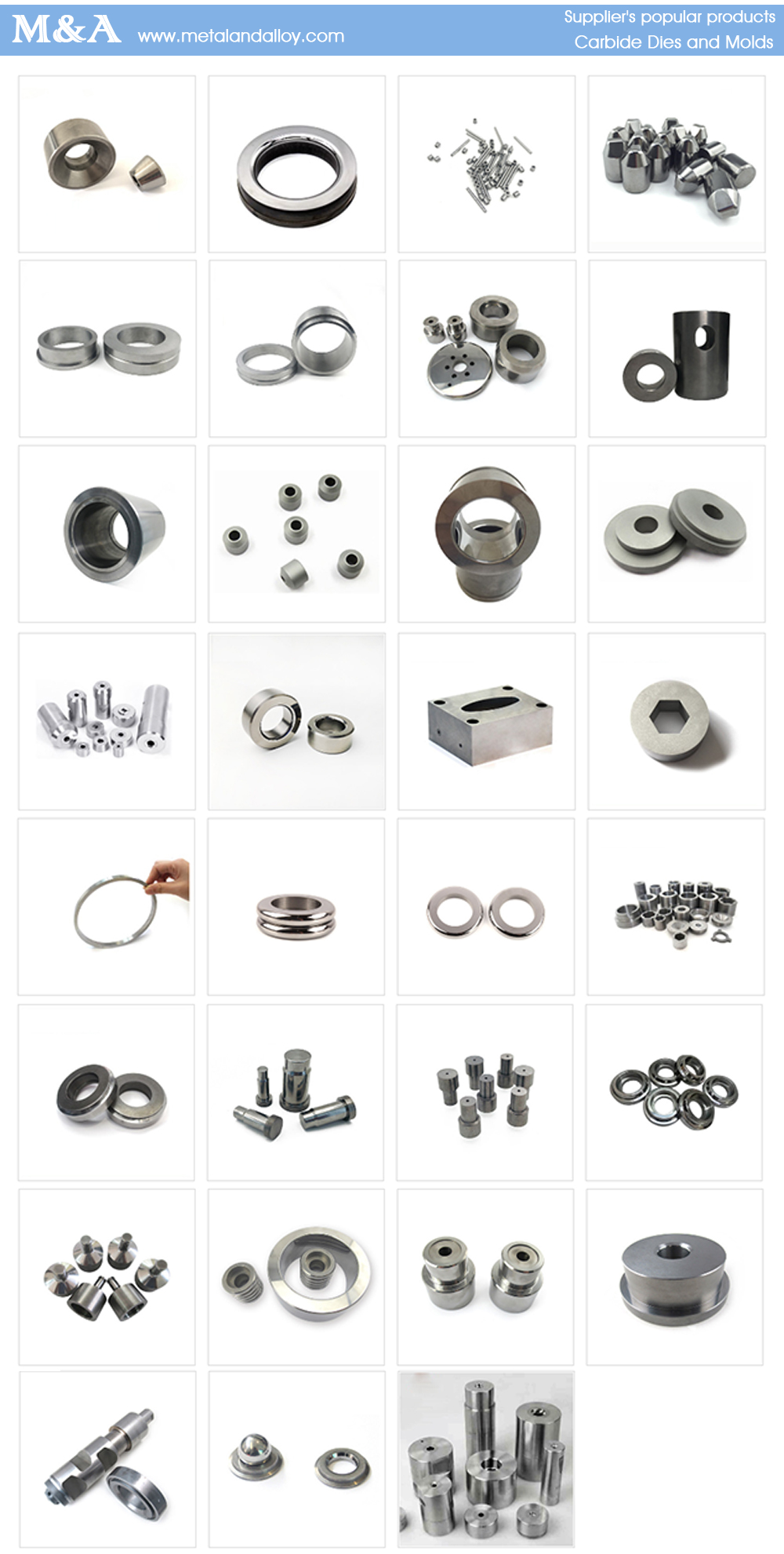

Products

Powder Mold Metallurgy Compacting Dies Tooling

Five Advantages Of Products

- Magnet powder metallurgy compacting die

- powder compaction tooling

- Powder Metallurgy Die Tooling

- Sintered parts for the automotive industry

- Die tooling for oil pump parts

Product Details

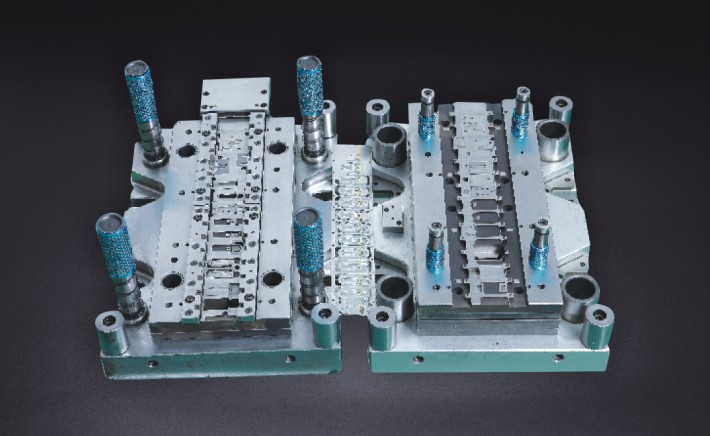

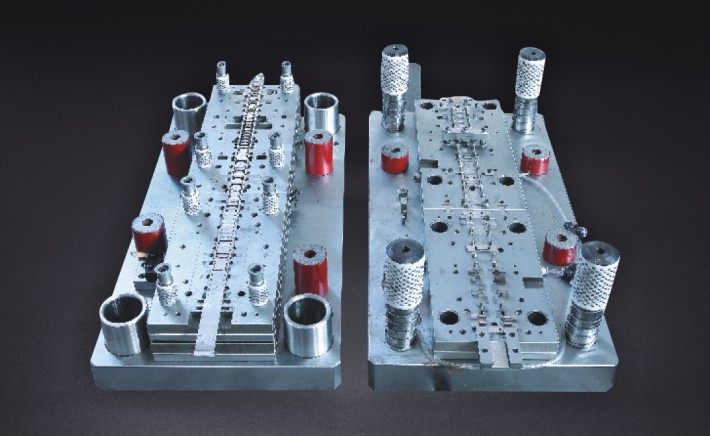

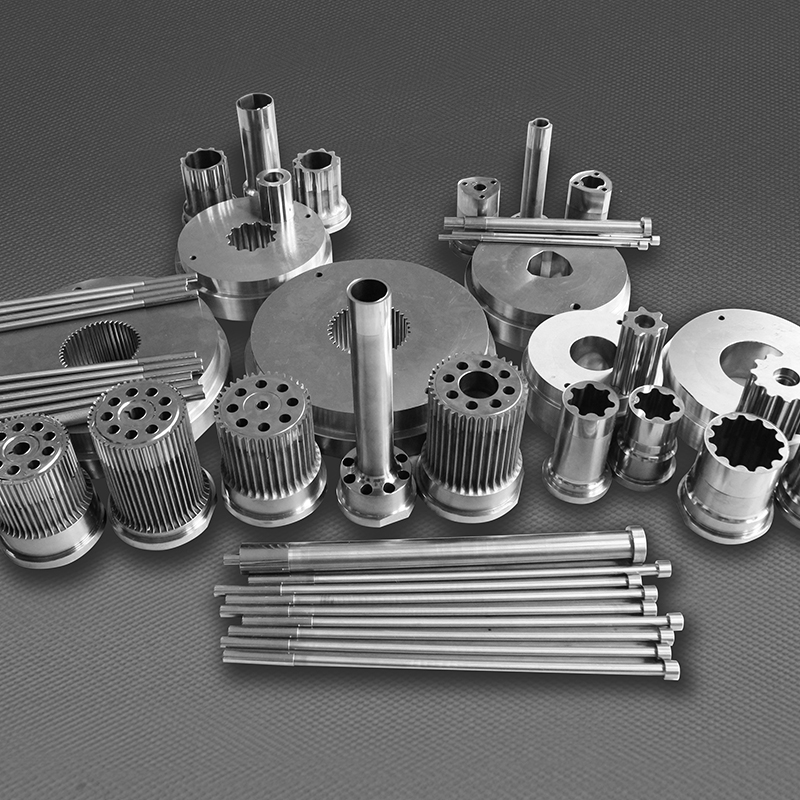

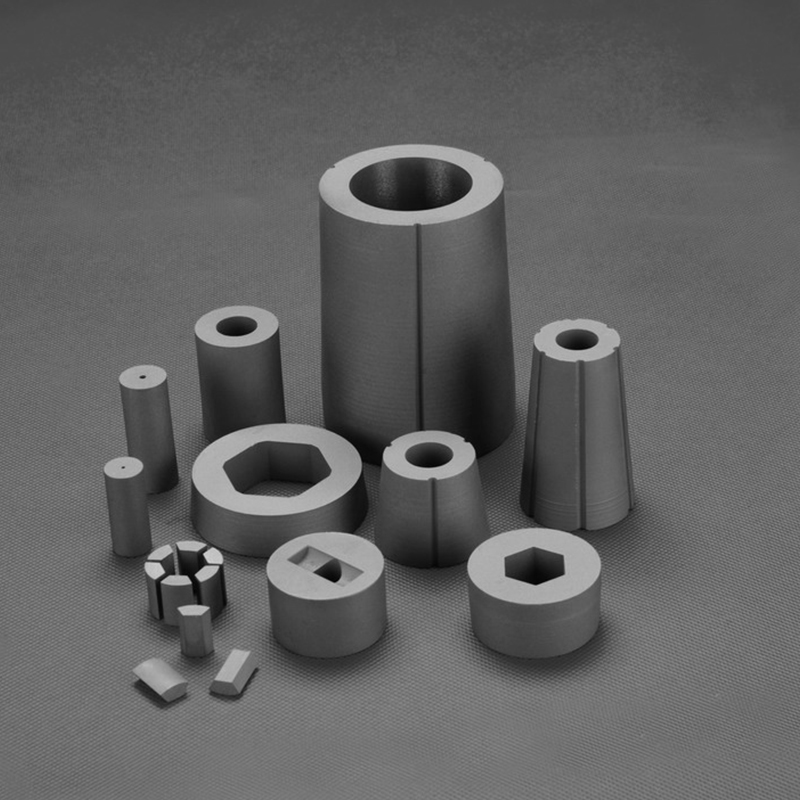

Powder Metallurgy Die Tooling, Powder compaction tooling

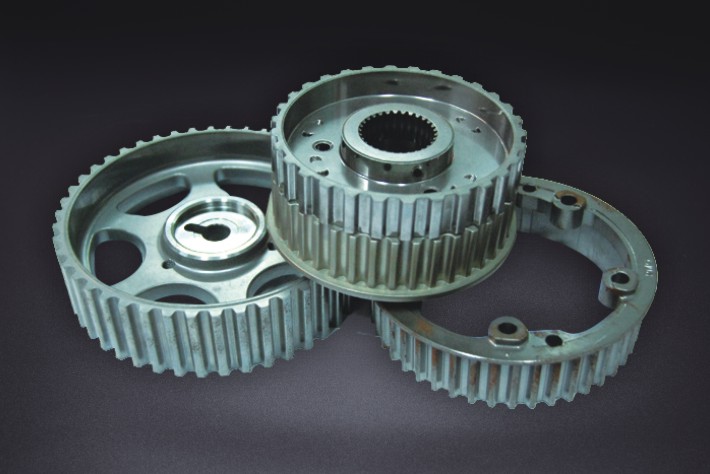

Sintered parts for the automotive industry.

Die tooling for oil pump parts, timing belt pulleys, clutch parts, ABS parts, door/trunk interlock parts, power steering parts, sunroof parts, synchro parts etc.

Sintered parts for household appliances and OA equipment.

Die tooling for exterior air-conditioner unit compressors, hard disk parts, small precision motor bearing parts etc.

Sintered parts are precision parts manufactured by press molding fine metal powder in a precision die (powder metallurgy die), which is then hardened by heating (sintering).

Popular for their high material yield rate and high precision, sintered parts are an essential part of the automotive and electrical appliance industries, making it possible to produce complex shapes and mass produce lightweight products.

In the PM process the following three steps are followed in sequence: mixing (or blending), compacting, and sintering.

Mixing: A homogeneous mixture of elemental metal powders or alloy powders is prepared. Depending upon the need, powders of other alloys or lubricants may be added.

Compacting: A controlled amount of the mixed powder is introduced into a precision die and then it is pressed or compacted at a pressure in the range 100 MPa to 1000 MPa. The compacting pressure required depends on the characteristics and shape of the particles, the method of mixing, and on the lubricant used. This is generally done at room temperature. In doing so, the loose powder is consolidated and densified into a shaped model. The model is generally called “green compact.” As is comes out of the die, the compact has the size and shape of the finished product. The strength of the compact is just sufficient for in – process handling and transportation to the sintering furnace.

BENEFITS OF TUNGSTEN CARBIDE IN TOOLING

Strength – Tungsten carbide has very high strength for a material and is extremely hard and rigid. Compressive strength is higher than almost all melted, cast, forged metals and alloys.

Rigidity – Tungsten carbide compositions range from (2) to (3) times as rigid as steel and (4) to (6) times as rigid as cast iron and brass. Young’s Modulus is up to 94,800,000 psi.

Heat Resistance – Tungsten Carbide is highly resistance to deformation and deflection and is very valuable in applications where a combination of minimum deflection and good ultimate strength is the first consideration.

Impact Resistant – For such a hard material with very high rigidity, the impact resistance is high.

Heat and oxidation resistance – Tungsten-base carbides perform well up to about 1000°F in oxidizing atmospheres and to 1500°F in non-oxidizing atmospheres

Low temperature resistance (cryogenic properties) – Tungsten carbide retains toughness and impact strength in the cryogenic temperature ranges. (-453°F.)

Thermal Conductivity – Tungsten carbide is in the range of twice that of tool steel and carbon steel.

Electrical Conductivity – Tungsten carbide is in the range equal to that of tool steel and carbon steel.

Specified Heat – Tungsten carbide ranges from about 50% to 70% as high as carbon steel.

Weight – The specific gravity of tungsten carbide is from 1-1/2 to 2 times that of carbon steel.

Hot Hardness – When temperature increases to 1400°F, tungsten carbide retains much of its room temperature hardness. At 1400°F, some grades equal the hardness of steels at room temperature.

Tolerances – Many surfaces or even complete parts can be used the way they come from the furnace, “as sintered”, such as mining or drilling compacts. In those parts requiring precision ground accuracy, such as stamping dies, close-tolerance preforms are provided for grinding or EDM.

Methods of Fastening – Tungsten carbide can be fastened to other materials by brazing, epoxy cementing or mechanical means. Tungsten carbide’s low thermal expansion rate must be carefully considered when preforms are provided for grinding or EDM.

Coefficient of Friction – Tungsten carbide compositions exhibit low dry coefficient of friction values as compared to steels.

Galling – Tungsten carbide compositions have exceptional resistance to galling and welding at the surface.

Corrosion-Wear Resistance – Specific grades are available with corrosion resistance approaching that of noble metals. Conventional grades have sufficient resistance to corrosion-wear conditions for many applications.

Wear-Resistance – Tungsten carbide wears up to 100 times longer than steel in conditions including abrasion, erosion and galling. Wear-resistance of tungsten carbide is better than that of wear-resistance tool steels.

MiXiao Tech

Contact Person: Michelle

Telephone: +86 13650157503

Landline: +86 13650157503

Company Address: Chang’.an Town,Dongguan City,Guangdong Province,China

Factory Address: Jinxia Industrial Zone,Chang’an Town,Dongguan City,Guangdong Province,China

Website: mixiao.us764.com

Previous: Raw Manufacturer Tungsten Carbide...

Powder Mold Metallurgy Compacting Dies Tooling

Colding Heading Dies Tungsten Carbide Molds

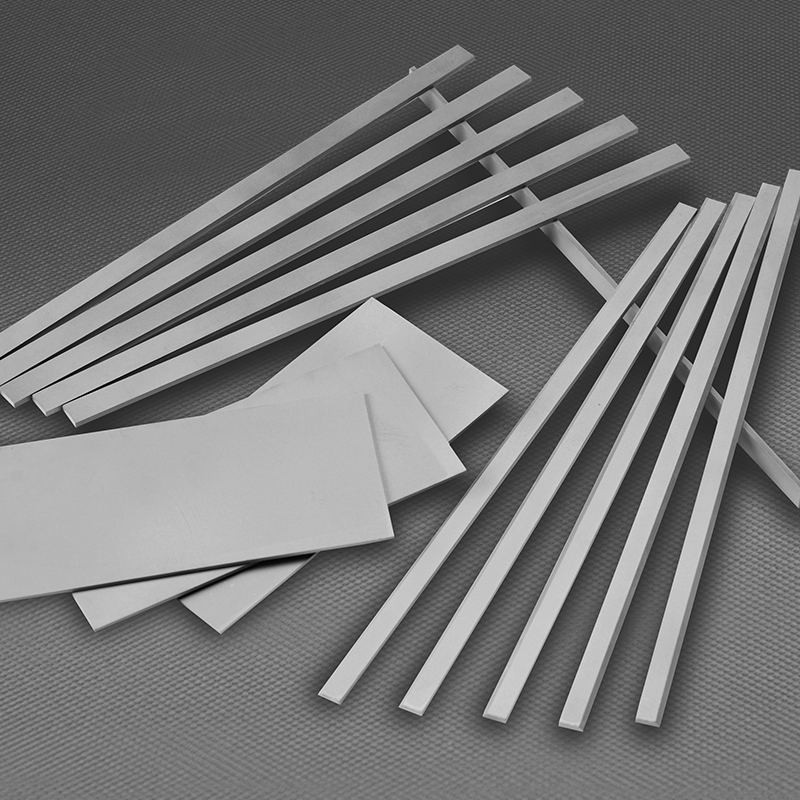

Cemented Tungsten Carbide Strips Bar

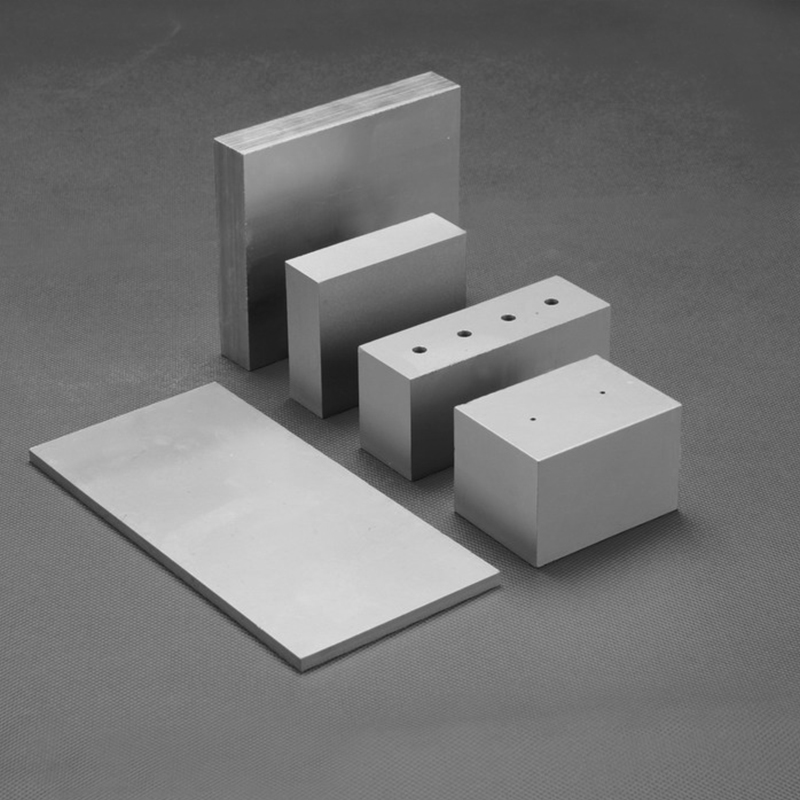

Tungsten Carbide Block Plate Strips

Tungsten Carbide Precision Rolls

Wear-Resistant Mold Blanks

Tungsten Carbide Punches Plates Cemented Sheet