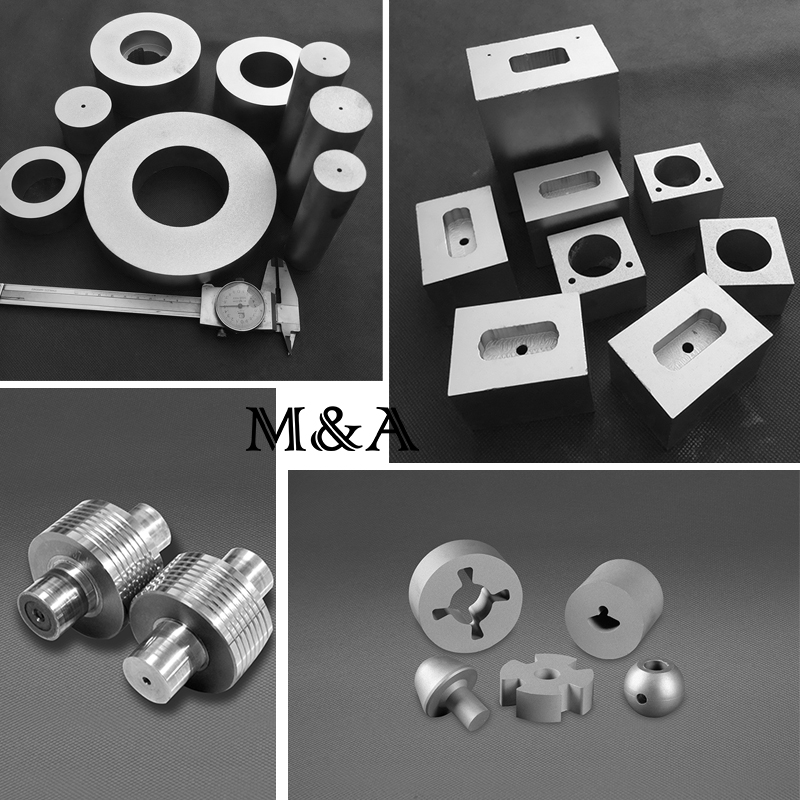

Products

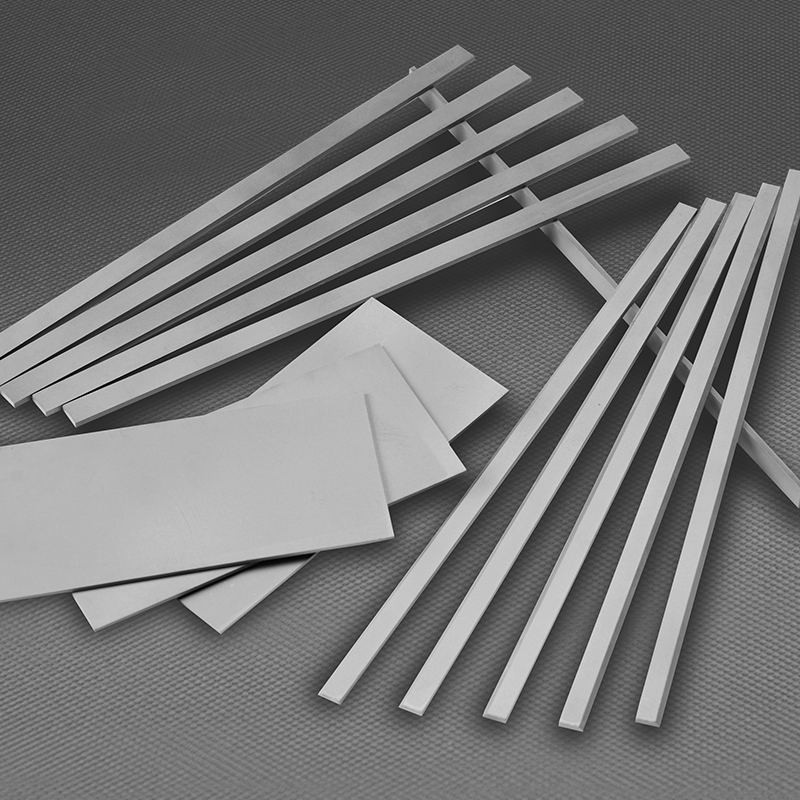

Tungsten Carbide Punches Plates Cemented Sheet

Five Advantages Of Products

- Wear resistance Tungsten carbide bulletproof plates

- Tungsten Carbide Sheet

- Blanks or polished grinding

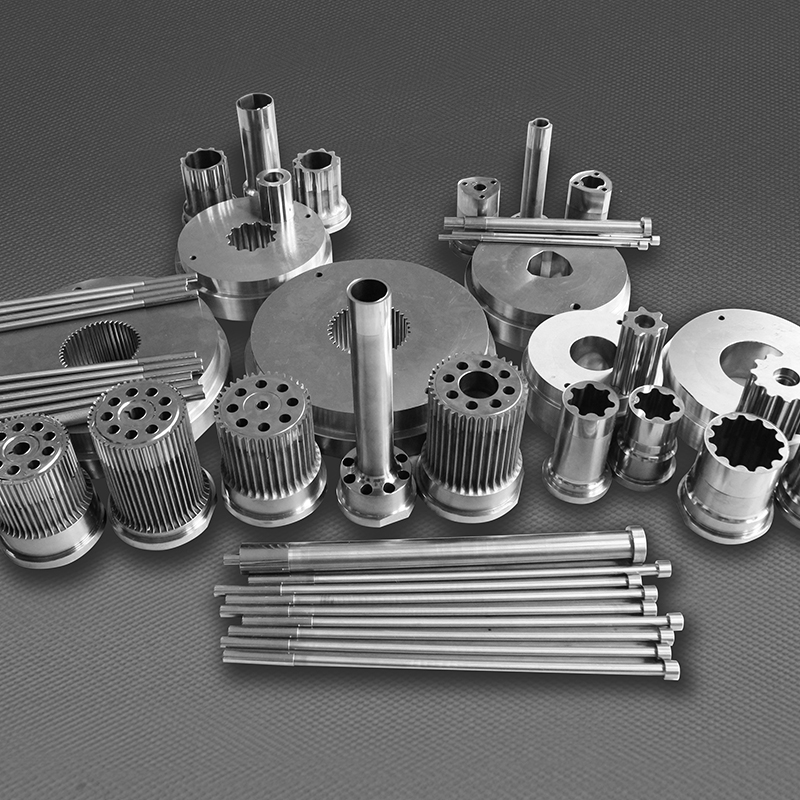

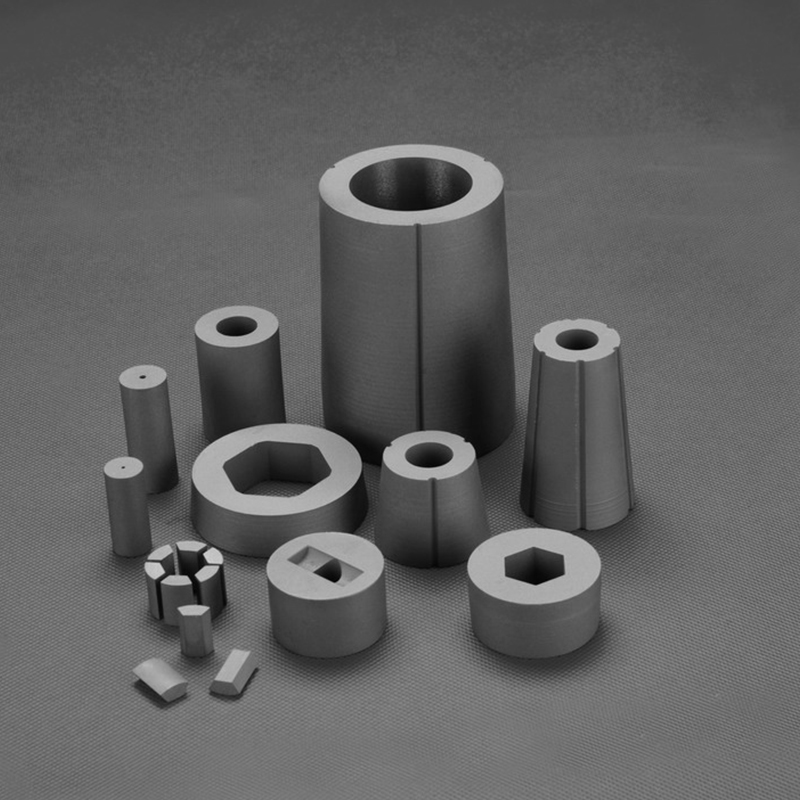

- Powder Metallurgy compacting dies

- Powder Metallurgy compacting dies

Product Details

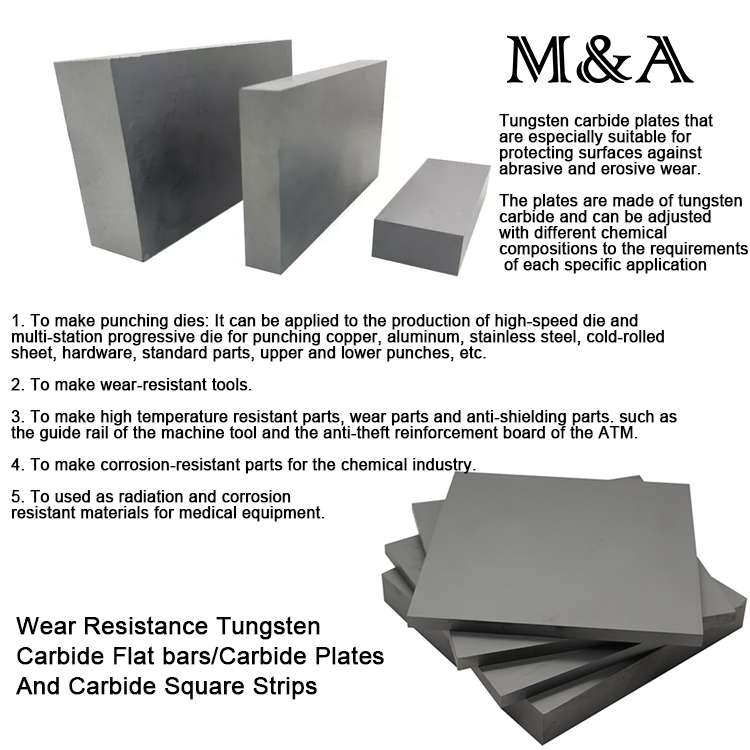

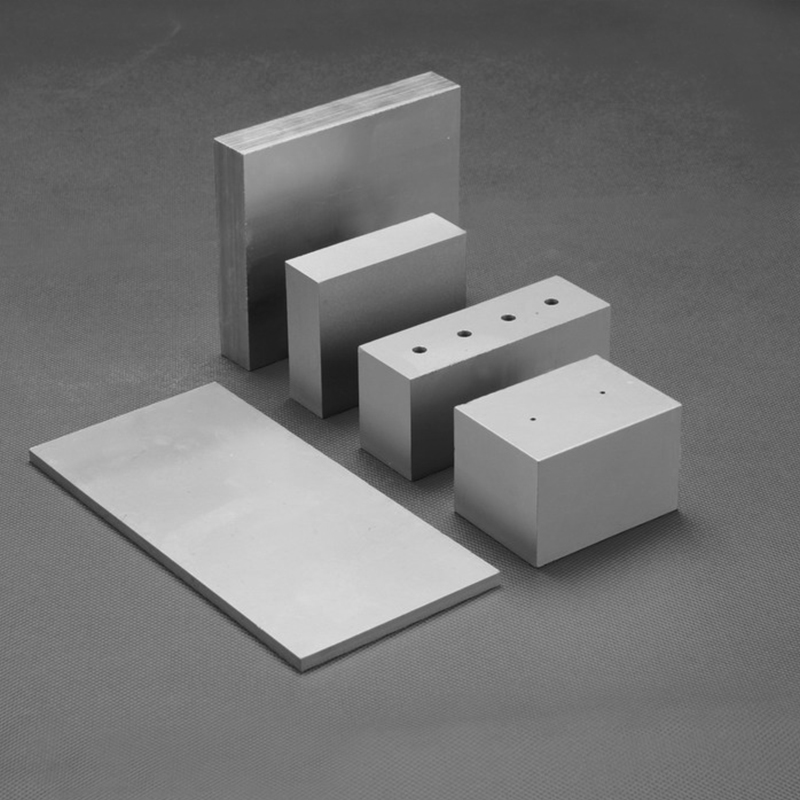

Tungsten Carbide Plate

Tungsten carbide plates are also named as tungsten carbide sheets, square plates, flat stock, and flat bars. They are made from

tungsten carbide, which is harder than many materials in terms of corrosion resistance and wear resistance. So they can be used in

woodworking, metal machining, and molding industry. All our carbide plates have been stress-relieving HIP sintered in order to

gain resistance to corrosion, pitting and cracking commonly experienced during machining.

Product Description

Tungsten carbide strips widely known as one kind of carbide cutting tools, it's available for different grinding geometric

parameters and suitable for both cutting materials and nonmetal materials, also it can be applied to conventional, carbide inserts semi-automatic lathe, automatic lathe and planning machine to work grooves and operate cutting

Tungsten carbide strip and sheet has the characteristics of high red-hardness, good weldability, high hardness and good wear resistance, it is mainly used for machining the solid wood, density board, grey cast iron, non-ferrous metal materials, chilled cast iron, quenched steel, PCB, braking materials. When used, should according to the specific purpose to choose the right material of tungsten carbide strip and sheet.

Our advantages of Tungsten Carbide strips:

1. 100% raw material tungsten carbide.

2. Sintered in HIP furnace

3. ISO9001: 2015 certificate.

4. Fully adopted in advance technology and equipment.

5. Professional manufacturer for tungsten carbide items over 16 years experience.

6. Quality Control System and strict inspection.

7. OEM and ODM are accepted as well.

Application Tungsten carbide wear protection plain insert:

1.Suitable for treating solid wood, shaving board and middle-density fiberboard.

2.Be used to make woodworking tools, such as forming tool, reamer, serrated knife blade and various blade.

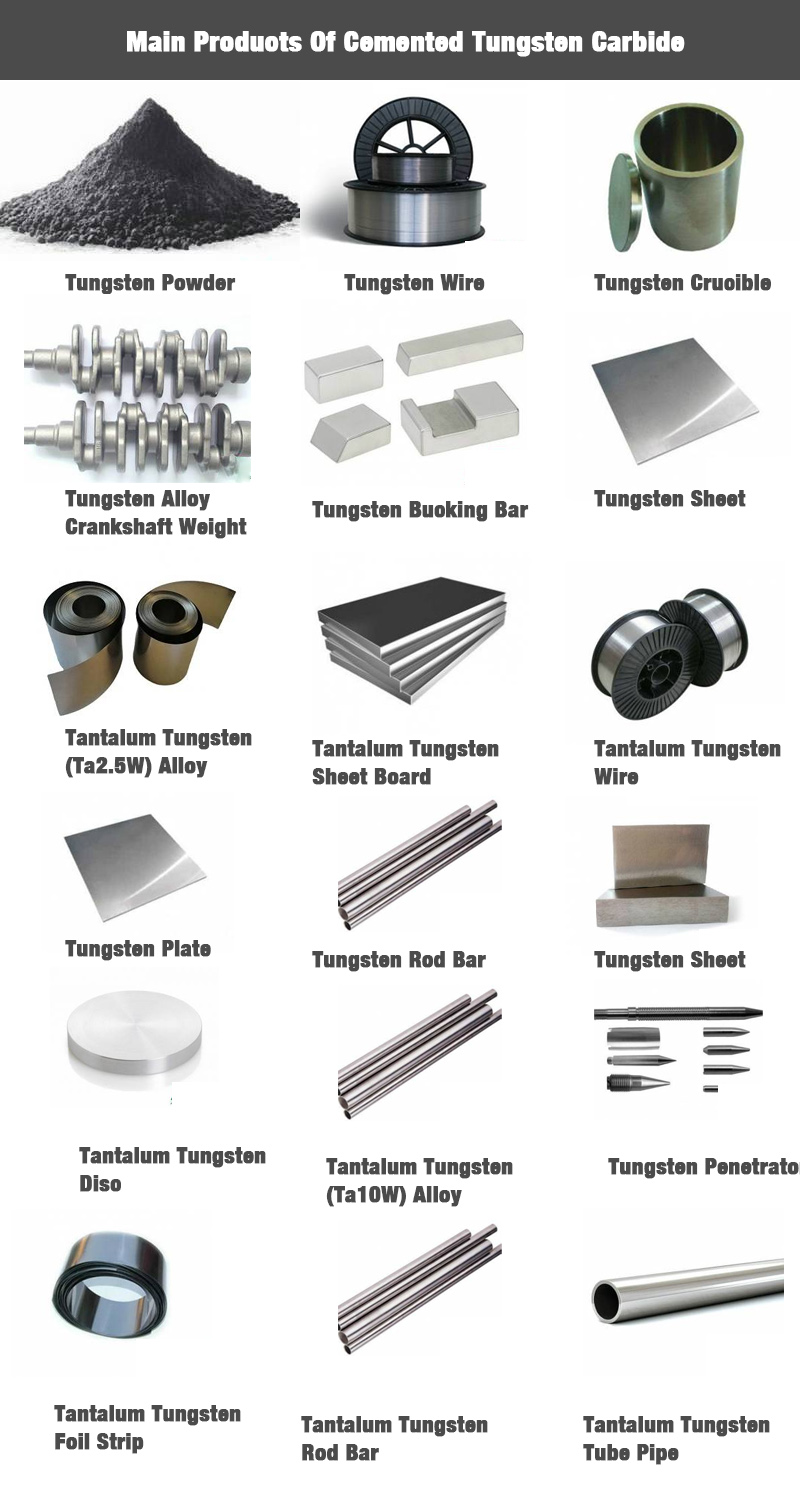

We can manufacture various cemented carbide strips and plate as per customer's requirement based on the different markets. Our main products include :Cemented carbide drills, cutting cutters, mining tools, drawing dies ,carbide stripes ,rods etc.

Skillful workers and advanced equipment can make every of your size possible. Different grade are available too.

We can supply standard and customized, polished and carbide plate.

Tungsten carbide plate

Purity: 99.95% min

Density: 14.7g/m3

Surface: Polished or blank or sand blast

Tungsten carbide plate Features

high temperature resistance

High wear-resistance corrosion-resistance

High pyroconductivity

excellent hardenability

Tungsten carbide plate Application

The tungsten carbide plate had widely application ranges and well effect.

Especially, the tungsten carbide plate is really good at machinery industry, metallurgy industry, aerospace development.

Advantages

◆High density

◆Good machinability

◆High modulus of elasticity

◆Strong corrosion resistance

◆Non-poisonous ,no pollution

◆Good mechanical properties

◆Harmless to the health and environments

◆It can effectively absorb X rays and gamma rays (the absorption of X rays andγ rays is higher than lead 30~40%)

BENEFITS OF TUNGSTEN CARBIDE IN TOOLING

Strength – Tungsten carbide has very high strength for a material and is extremely hard and rigid. Compressive strength is higher than almost all melted, cast, forged metals and alloys.

Rigidity – Tungsten carbide compositions range from (2) to (3) times as rigid as steel and (4) to (6) times as rigid as cast iron and brass. Young’s Modulus is up to 94,800,000 psi.

Heat Resistance – Tungsten Carbide is highly resistance to deformation and deflection and is very valuable in applications where a combination of minimum deflection and good ultimate strength is the first consideration.

Impact Resistant – For such a hard material with very high rigidity, the impact resistance is high.

Heat and oxidation resistance – Tungsten-base carbides perform well up to about 1000°F in oxidizing atmospheres and to 1500°F in non-oxidizing atmospheres

Low temperature resistance (cryogenic properties) – Tungsten carbide retains toughness and impact strength in the cryogenic temperature ranges. (-453°F.)

Thermal Conductivity – Tungsten carbide is in the range of twice that of tool steel and carbon steel.

Electrical Conductivity – Tungsten carbide is in the range equal to that of tool steel and carbon steel.

Specified Heat – Tungsten carbide ranges from about 50% to 70% as high as carbon steel.

Weight – The specific gravity of tungsten carbide is from 1-1/2 to 2 times that of carbon steel.

Hot Hardness – When temperature increases to 1400°F, tungsten carbide retains much of its room temperature hardness. At 1400°F, some grades equal the hardness of steels at room temperature.

Tolerances – Many surfaces or even complete parts can be used the way they come from the furnace, “as sintered”, such as mining or drilling compacts. In those parts requiring precision ground accuracy, such as stamping dies, close-tolerance preforms are provided for grinding or EDM.

Methods of Fastening – Tungsten carbide can be fastened to other materials by brazing, epoxy cementing or mechanical means. Tungsten carbide’s low thermal expansion rate must be carefully considered when preforms are provided for grinding or EDM.

Coefficient of Friction – Tungsten carbide compositions exhibit low dry coefficient of friction values as compared to steels.

Galling – Tungsten carbide compositions have exceptional resistance to galling and welding at the surface.

Corrosion-Wear Resistance – Specific grades are available with corrosion resistance approaching that of noble metals. Conventional grades have sufficient resistance to corrosion-wear conditions for many applications.

Wear-Resistance – Tungsten carbide wears up to 100 times longer than steel in conditions including abrasion, erosion and galling. Wear-resistance of tungsten carbide is better than that of wear-resistance tool steels.

MiXiao Tech

Contact Person: Michelle

Telephone: +86 13650157503

Landline: +86 13650157503

Company Address: Chang’.an Town,Dongguan City,Guangdong Province,China

Factory Address: Jinxia Industrial Zone,Chang’an Town,Dongguan City,Guangdong Province,China

Website: mixiao.us764.com

Previous: Cemented Tungsten Carbide Strips Bar

Powder Mold Metallurgy Compacting Dies Tooling

Colding Heading Dies Tungsten Carbide Molds

Cemented Tungsten Carbide Strips Bar

Tungsten Carbide Block Plate Strips

Tungsten Carbide Precision Rolls

Wear-Resistant Mold Blanks

Tungsten Carbide Punches Plates Cemented Sheet