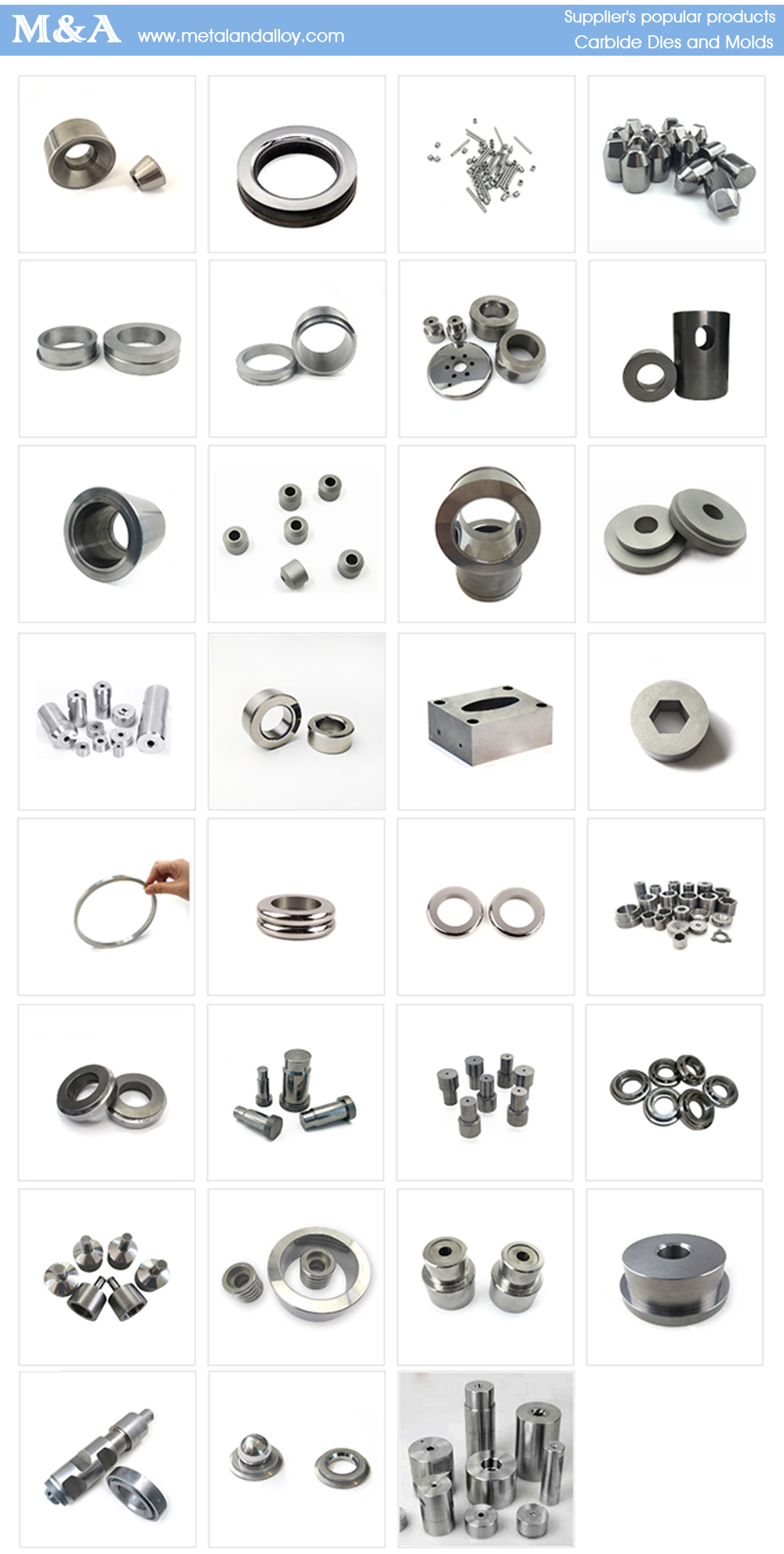

Products

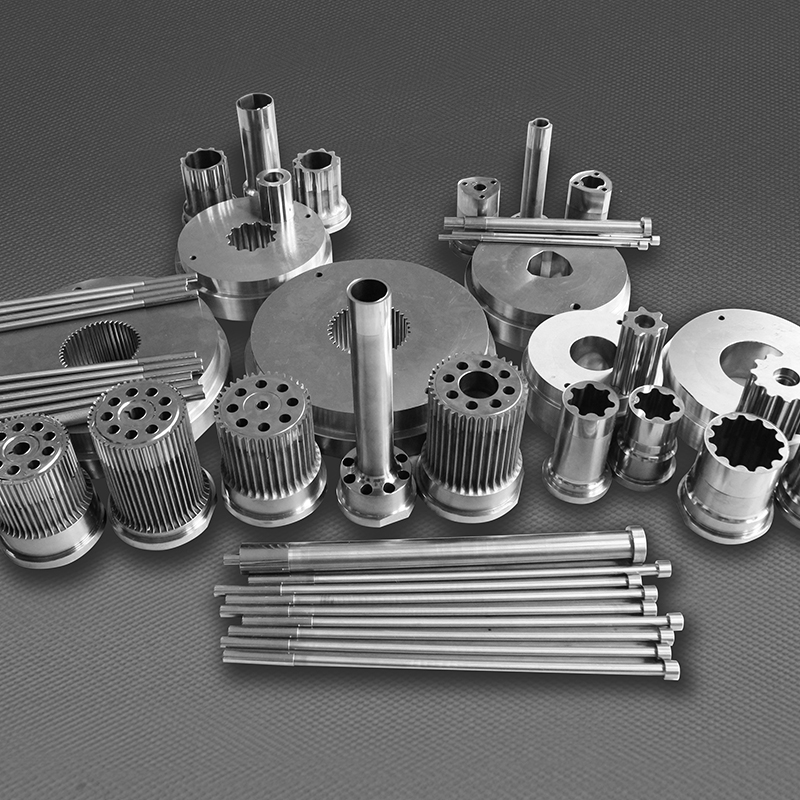

Tungsten Carbide Precision Rolls

Five Advantages Of Products

- Tungsten Carbide Rolls

- tungsten carbide rollers

- Cemented carbide roll collar

- Cemented carbide roll collar

- Cemented carbide roll collar

Product Details

Tungsten carbide rolls for hot rolling of long steel products such as wire, bars, and tubes as well as clamping systems

M&A Materials integral rolls provide the strongest design available for the early and intermediate stands in your mill. They are best suited for the highest rolling torque and force and low rolling speeds, even below 1 m/sec. The cast iron arbor and the cemented tungsten carbide rings are cast and machined in one solid piece, with no keys, no keyways, and no locking nut. This permits torque transmission higher than that of conventional combi rolls. Also, because there is no locking device that takes up space, more passforms are available for productive hot rolling.

M&A product specialists are available to help you determine the best solution for all your hot rolling needs.

Introduction

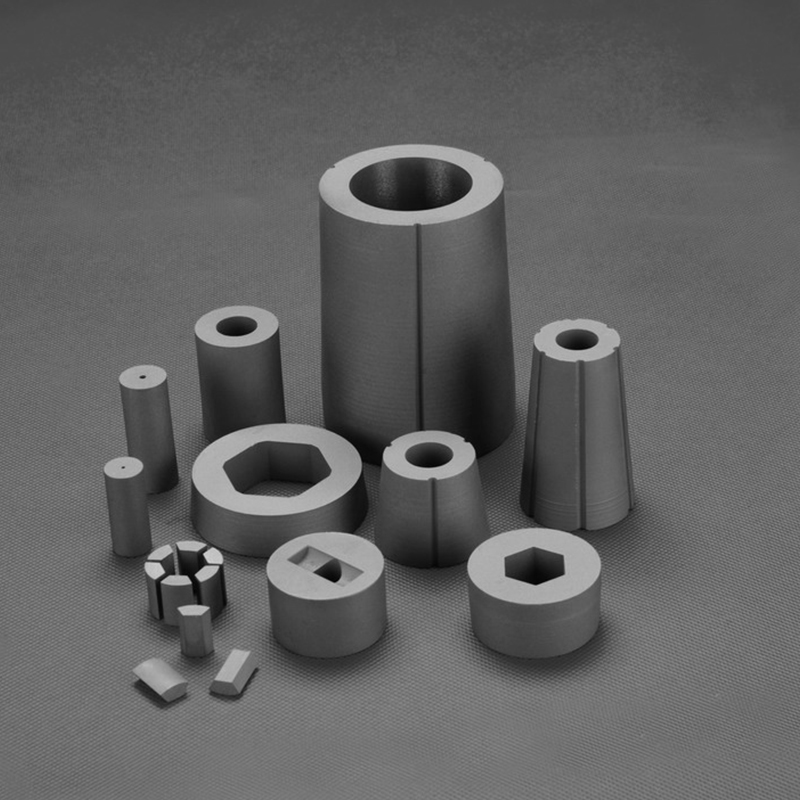

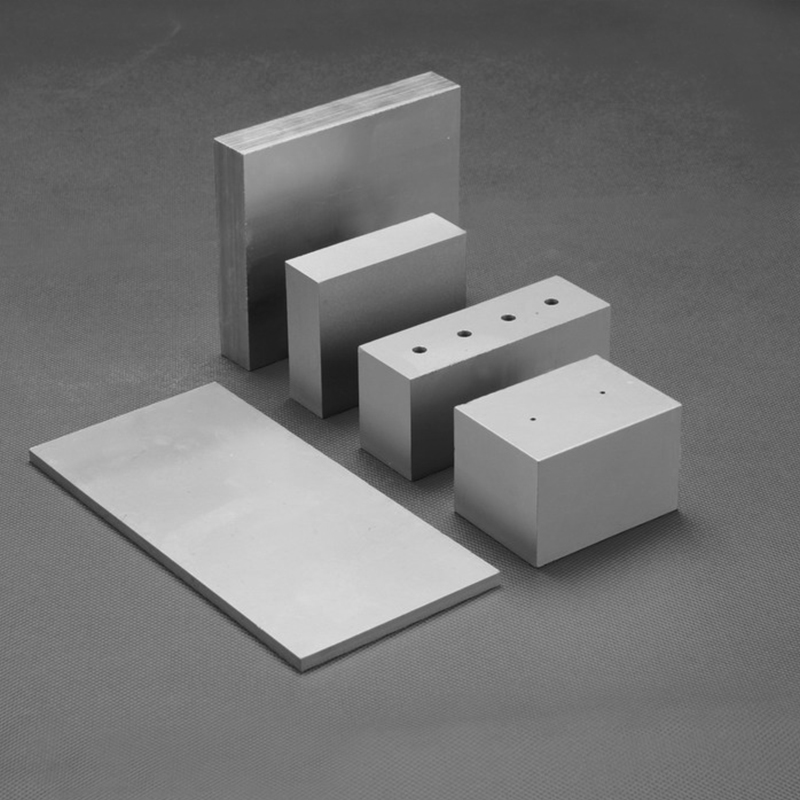

Cemented carbide roll collar (also called tungsten carbide rollers) refers to the roll made from tungsten carbide and cobalt by powder metallurgy. Tungsten carbide rollers are available in both integral and combined versions. They have excellent performance, stable quality, high processing precision, good wear resistance, and high impact resistance.

With the increasingly fierce competition in the quality and price of steel products, steel companies are constantly updating their equipment technology to continuously increase the rolling speed of rolling mills. At the same time, how to reduce the rolling mill downtime and further improve the effective operation rate of rolling mills? It has become an important topic for rolling steel engineers. The use of roll materials with higher rolling life is one of the important means to achieve this goal.

Due to its good wear resistance, high-temperature red hardness, thermal fatigue resistance, and high strength cemented carbide rolls have been widely used in the production of wire rods, rebars and seamless steel tubes, which greatly improved the work efficiency of the rolling mill. A variety of different grades of carbide rings have been developed based on the differences in the working conditions of the different racks and rolls.

Parameters

Tungsten carbide rollers can be divided into solid carbide rolls and composite hard alloy rolls according to the structure. Solid carbide rolls have been widely used in pre-finishing and finishing stands for high-speed wire rod mills (including fixed reduction racks, pinch roll stands).

The composite cemented carbide roll is made of cemented carbide and other materials and can be divided into hard alloy composite roll ring and solid carbide composite roll. The cemented carbide composite roll ring is mounted on the roller shaft; for the solid carbide composite roll, cemented carbide roll ring is directly cast into the roll shaft to form an entirety, which is applied to the rolling mill with the large rolling load.

Features

Property

The tungsten carbide rollers have high hardness, and its hardness changes very little with temperature changes. The hardness at 700 °C is 4 times that of high-speed steel; and the elastic modulus, compressive strength, flexural strength, and thermal conductivity are also over 1 times higher than tool steel.

Since the thermal conductivity of the cemented carbide roll is high, the heat dissipation effect is good, and the time at which the surface of the roll is at a high temperature is short so that the high-temperature reaction time between the roll and the harmful impurities in the cooling water is short. Therefore, the cemented carbide roll is more resistant to corrosion and cold and hot fatigue than the tool steel roll.

MiXiao Tech

Contact Person: Michelle

Telephone: +86 13650157503

Landline: +86 13650157503

Company Address: Chang’.an Town,Dongguan City,Guangdong Province,China

Factory Address: Jinxia Industrial Zone,Chang’an Town,Dongguan City,Guangdong Province,China

Website: mixiao.us764.com

Previous: Colding Heading Dies Tungsten Car...

Next: No

Powder Mold Metallurgy Compacting Dies Tooling

Colding Heading Dies Tungsten Carbide Molds

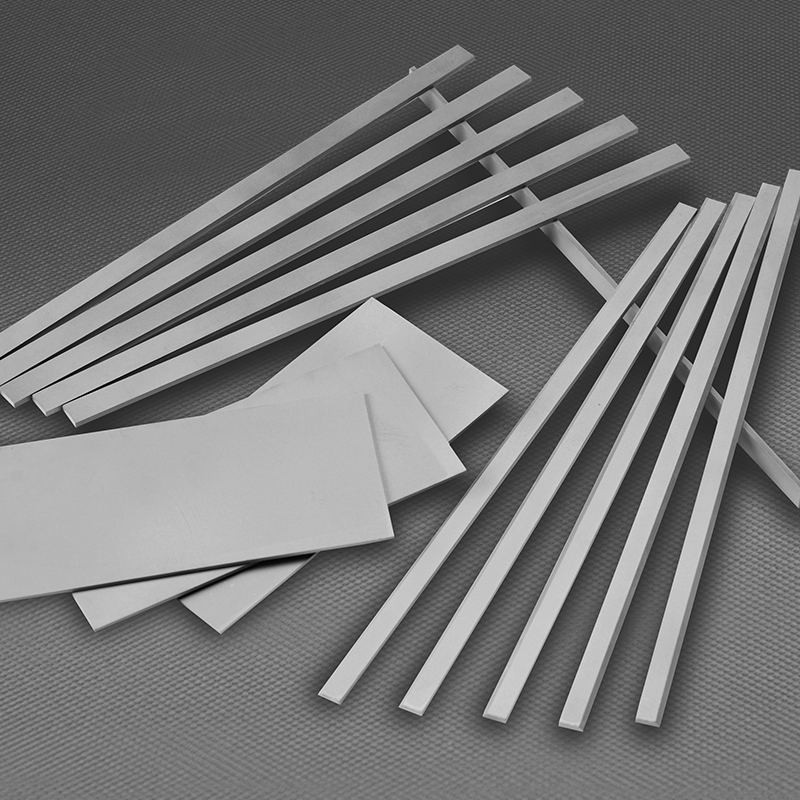

Cemented Tungsten Carbide Strips Bar

Tungsten Carbide Block Plate Strips

Tungsten Carbide Precision Rolls

Wear-Resistant Mold Blanks

Tungsten Carbide Punches Plates Cemented Sheet