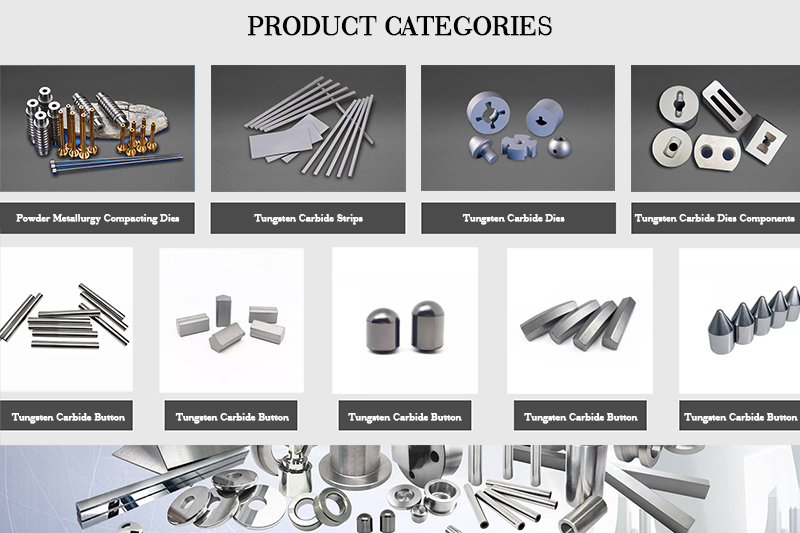

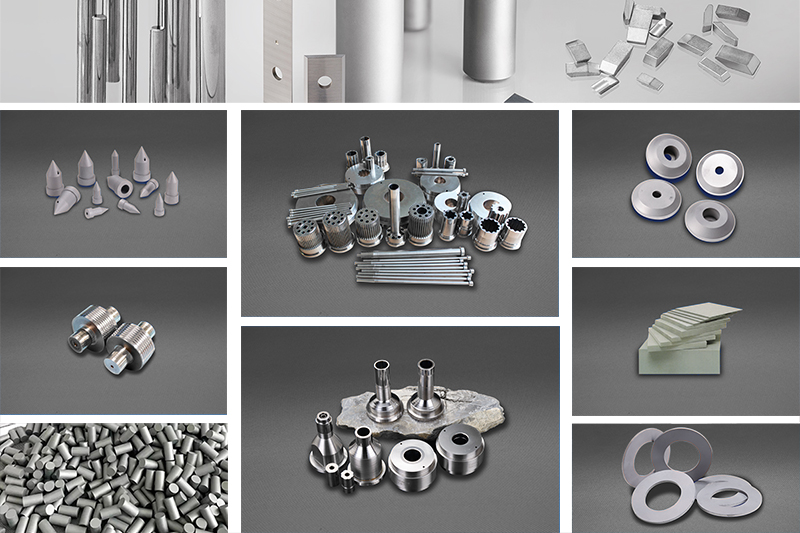

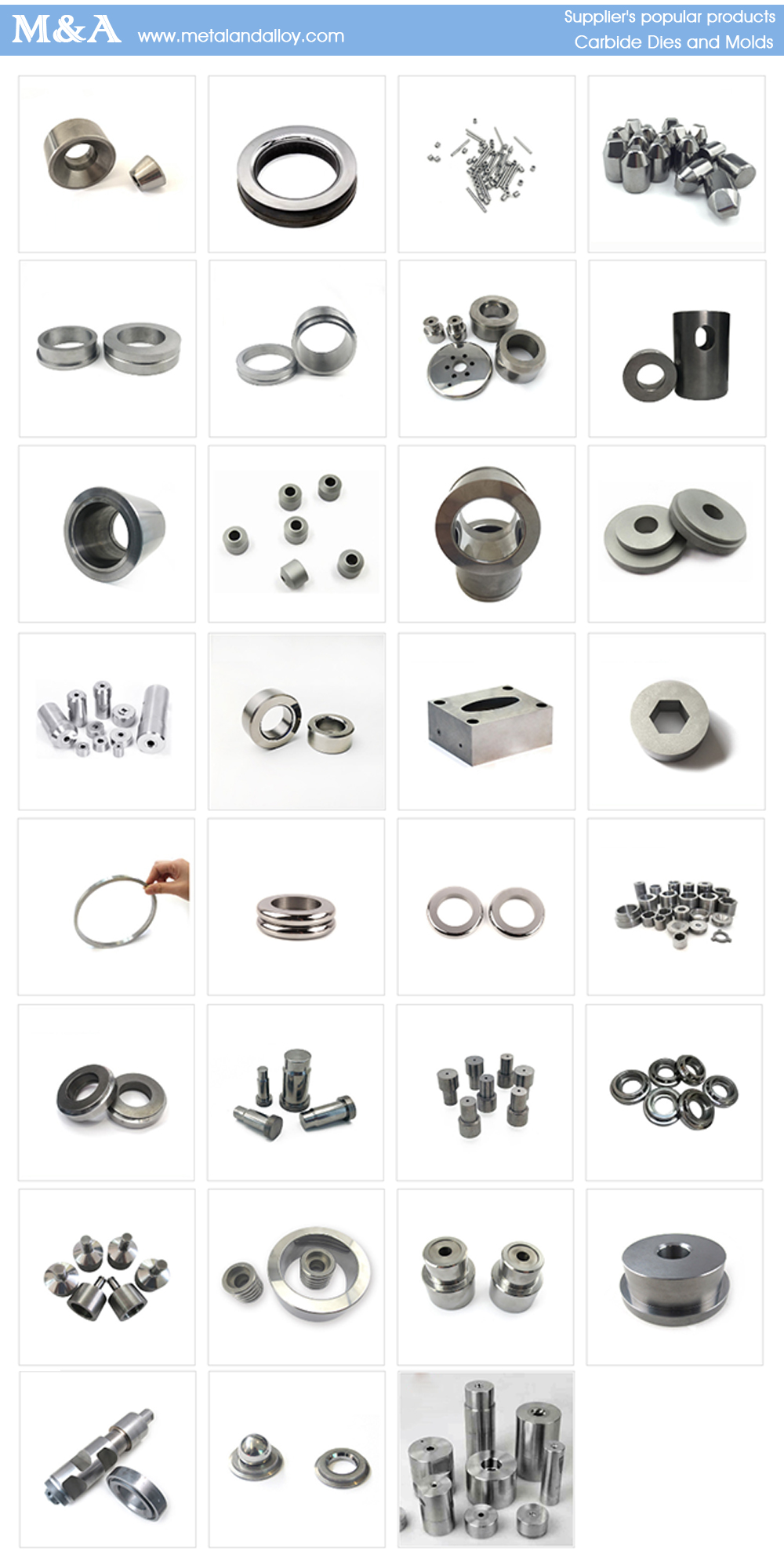

Products

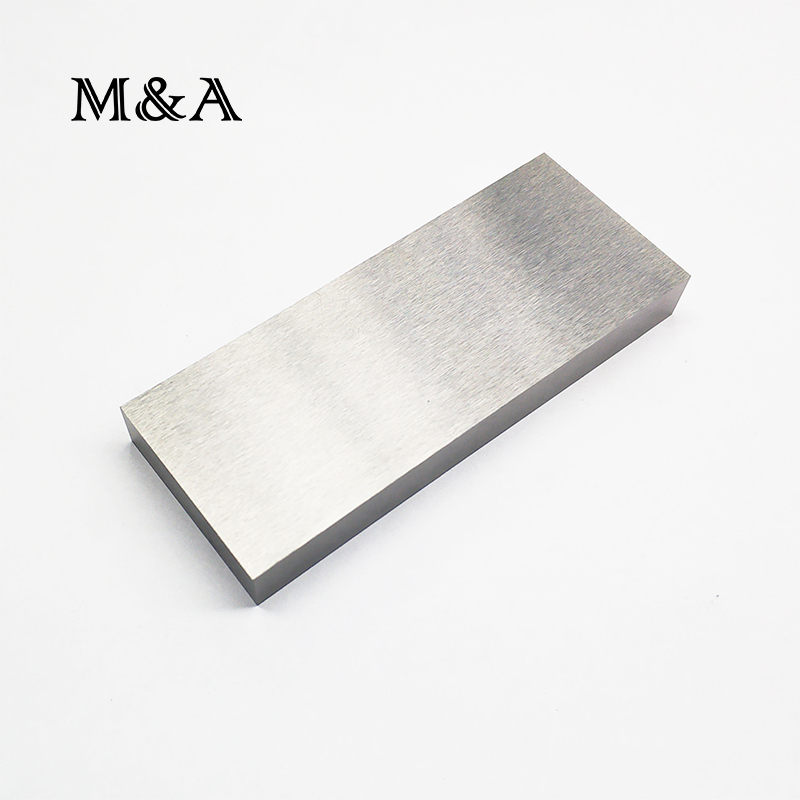

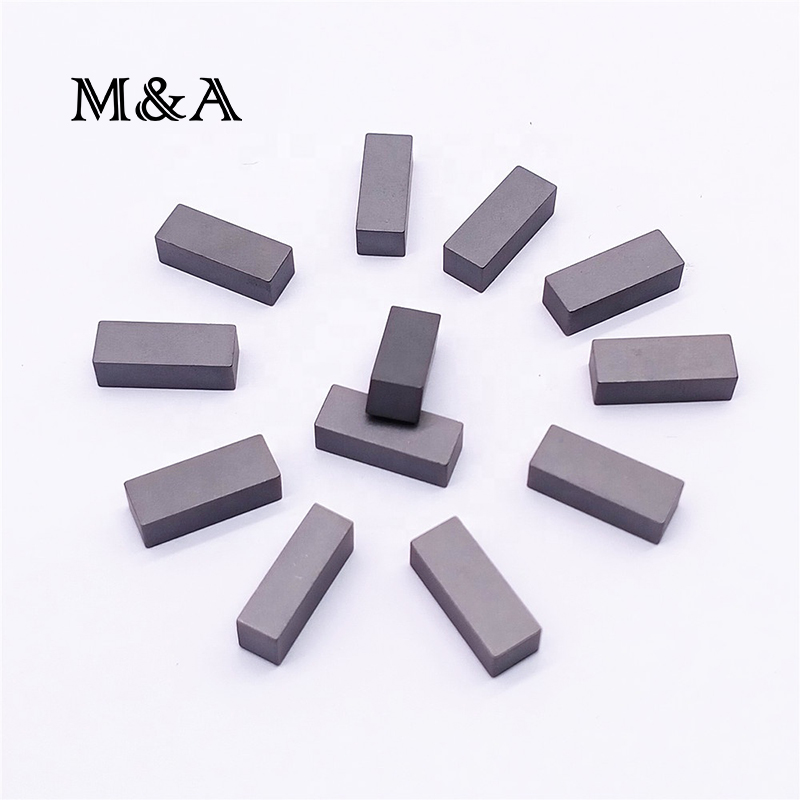

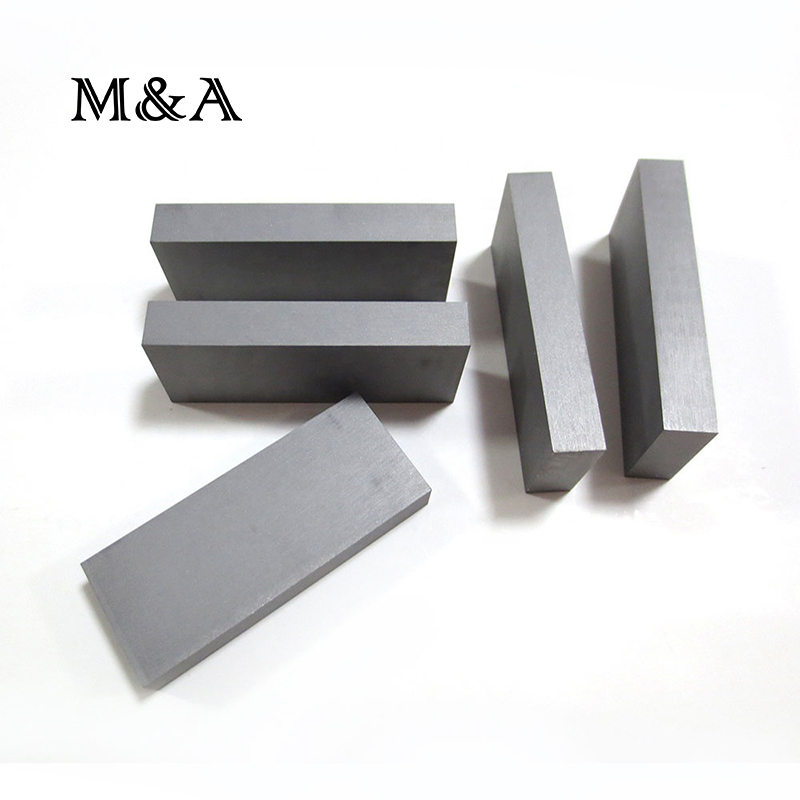

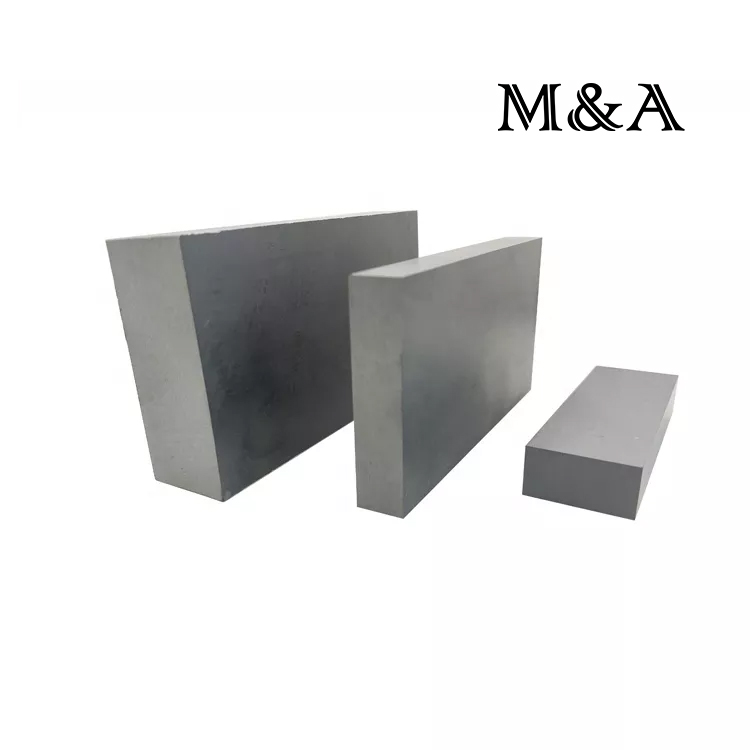

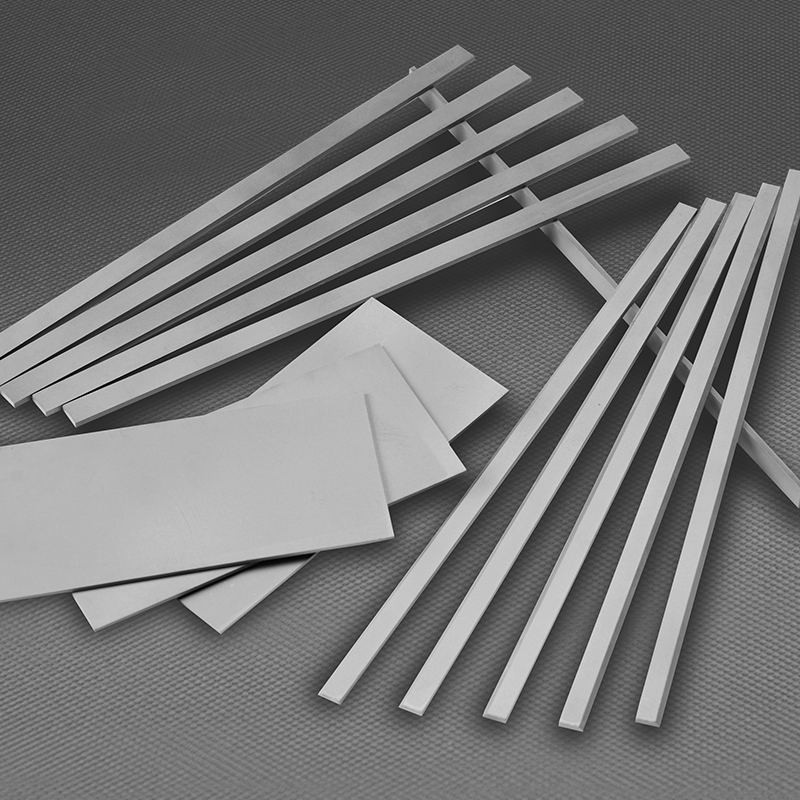

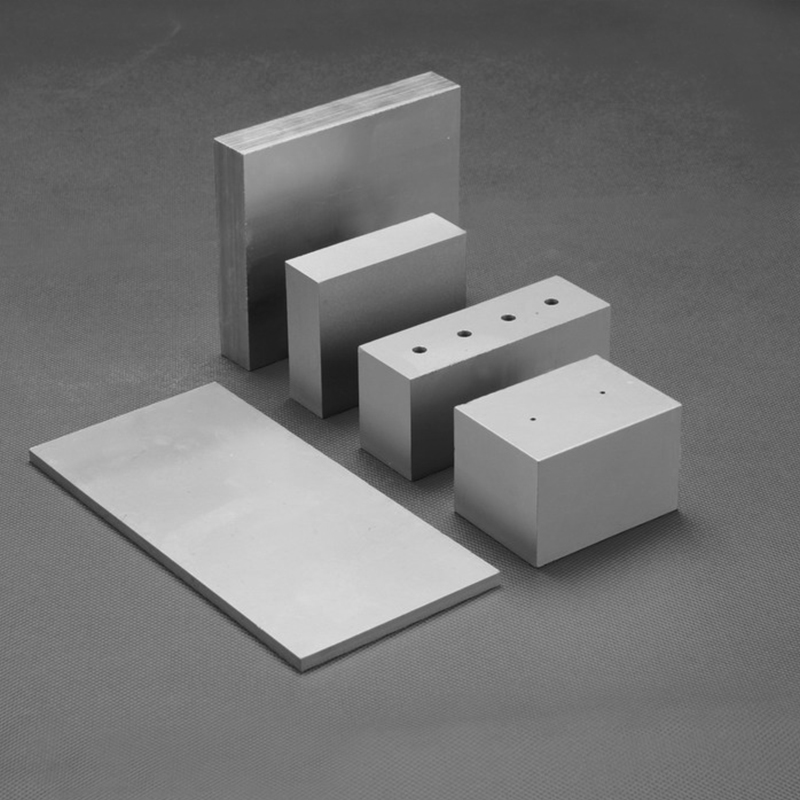

Tungsten Carbide Block Plate Strips

Five Advantages Of Products

- having all kind sizes for your choose,can supply less than 400mm length.

- Sintere by vacuum sintering furnace and HIP machine with excellent specifications without any hole.

- supply blank plate with tolerance(-0.15~+0.15)or (0~+0.3).

- can grinding and polishing the side and blading.

- tungsten carbide block strips

Product Details

Descriptions Of Tungsten

Tungsten also referred to as Wolfram, is a chemical element with the chemical symbol W and atomic number 74. After Carbon, Tungsten has the highest melting point of all elements. Tungsten is among the heaviest metals found on Earth. It has excellent high-temperature mechanical properties, with the lowest expansion coefficient and highest conductivity of all metals.

MiXiao Metal & Alloy is a leading supplier of Tungsten products. We offer competitive pricing and great lead times on all our materials, and we're capable of supplying custom materials per any specs/drawings you provide us with.

Tungsten carbide tip plate is suitable for semi-finishing the chilled cast iron, nonferrous metal and its alloy. It is also suitable for semi-finishing and finishing the hardened steel and alloy steel.Tungsten Carbide Non-magnetic Alloy comes in a variety of sizes & grades, the common types are always in stock, we can recommend grade for different applications, we can also manufacture the products according to clients' drawings or samples.

A. Over pressure sintering tungsten carbide plates have excellent red toughness,high hardness,good wear resistance,high elastic modulus,high strength,good chemical stability,acid,alkali,high temperature oxidation),Low impact toughness,low expansion coefficient,thermal conductivity,the characteristics of the conductive similar to iron and other alloy.

1. having all kind sizes for your choose,can supply less than 400mm length.

2. Sintere by vacuum sintering furnace and HIP machine with excellent specifications without any hole.

3. supply blank plate with tolerance(-0.15~+0.15)or (0~+0.3).

4. can grinding and polishing the side and blading.

Application of Tungsten carbide strips :

1,YG6 - Qualified for finish machining and semi-machining for the cast iron, non-ferrous metal, alloy and unalloyed materials.Also qualified for wire drawing for the steel and non-ferrous metal, electric drill for geology use and steel drill etc.

2,YG8 - Qualified for rough machining of cast iron, non-ferrus metal, nonmetal materials, drawing of steel, non-ferrous metal and pipes, various drills for geology use, tools for machine manufacture and wearing parts.

3,YG15 - Qualified for hard rock drilling, steel bars with high compression ratios, pipe drawing, punching tools, core cabinet of powder metallurgy automatic molders etc.

Note:Welcome OEM&ODM.The size and purity can be customized as requirements.

BENEFITS OF TUNGSTEN CARBIDE IN TOOLING

Strength – Tungsten carbide has very high strength for a material and is extremely hard and rigid. Compressive strength is higher than almost all melted, cast, forged metals and alloys.

Rigidity – Tungsten carbide compositions range from (2) to (3) times as rigid as steel and (4) to (6) times as rigid as cast iron and brass. Young’s Modulus is up to 94,800,000 psi.

Heat Resistance – Tungsten Carbide is highly resistance to deformation and deflection and is very valuable in applications where a combination of minimum deflection and good ultimate strength is the first consideration.

Impact Resistant – For such a hard material with very high rigidity, the impact resistance is high.

Heat and oxidation resistance – Tungsten-base carbides perform well up to about 1000°F in oxidizing atmospheres and to 1500°F in non-oxidizing atmospheres

Low temperature resistance (cryogenic properties) – Tungsten carbide retains toughness and impact strength in the cryogenic temperature ranges. (-453°F.)

Thermal Conductivity – Tungsten carbide is in the range of twice that of tool steel and carbon steel.

Electrical Conductivity – Tungsten carbide is in the range equal to that of tool steel and carbon steel.

Specified Heat – Tungsten carbide ranges from about 50% to 70% as high as carbon steel.

Weight – The specific gravity of tungsten carbide is from 1-1/2 to 2 times that of carbon steel.

Hot Hardness – When temperature increases to 1400°F, tungsten carbide retains much of its room temperature hardness. At 1400°F, some grades equal the hardness of steels at room temperature.

Tolerances – Many surfaces or even complete parts can be used the way they come from the furnace, “as sintered”, such as mining or drilling compacts. In those parts requiring precision ground accuracy, such as stamping dies, close-tolerance preforms are provided for grinding or EDM.

Methods of Fastening – Tungsten carbide can be fastened to other materials by brazing, epoxy cementing or mechanical means. Tungsten carbide’s low thermal expansion rate must be carefully considered when preforms are provided for grinding or EDM.

Coefficient of Friction – Tungsten carbide compositions exhibit low dry coefficient of friction values as compared to steels.

Galling – Tungsten carbide compositions have exceptional resistance to galling and welding at the surface.

Corrosion-Wear Resistance – Specific grades are available with corrosion resistance approaching that of noble metals. Conventional grades have sufficient resistance to corrosion-wear conditions for many applications.

Wear-Resistance – Tungsten carbide wears up to 100 times longer than steel in conditions including abrasion, erosion and galling. Wear-resistance of tungsten carbide is better than that of wear-resistance tool steels.

Surface Finishes – Finish of an as-sintered part will be about 50 micro inches. Surface, cylindrical or internal grinding with diamond wheel will produce 18 micro inches or better and can produce as low as 4 to 8 micro inches. Diamond lapping and honing can produce 2 micro inches and with polishing as low as 1/2 micro inch.

MiXiao Tech

Contact Person: Michelle

Telephone: +86 13650157503

Landline: +86 13650157503

Company Address: Chang’.an Town,Dongguan City,Guangdong Province,China

Factory Address: Jinxia Industrial Zone,Chang’an Town,Dongguan City,Guangdong Province,China

Website: mixiao.us764.com

Previous: Carbide Tips China Raw Manufactur...

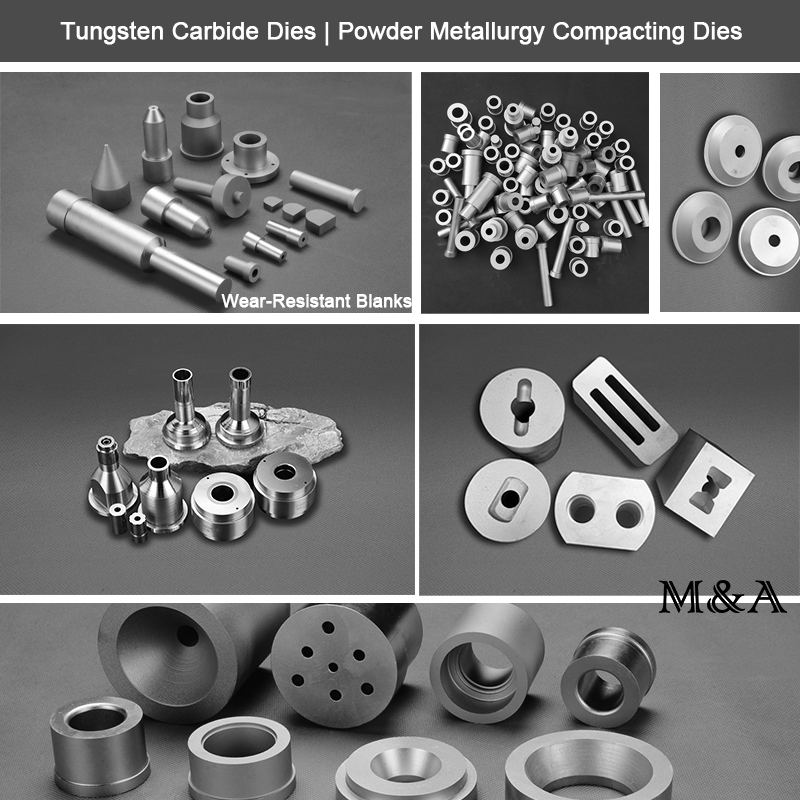

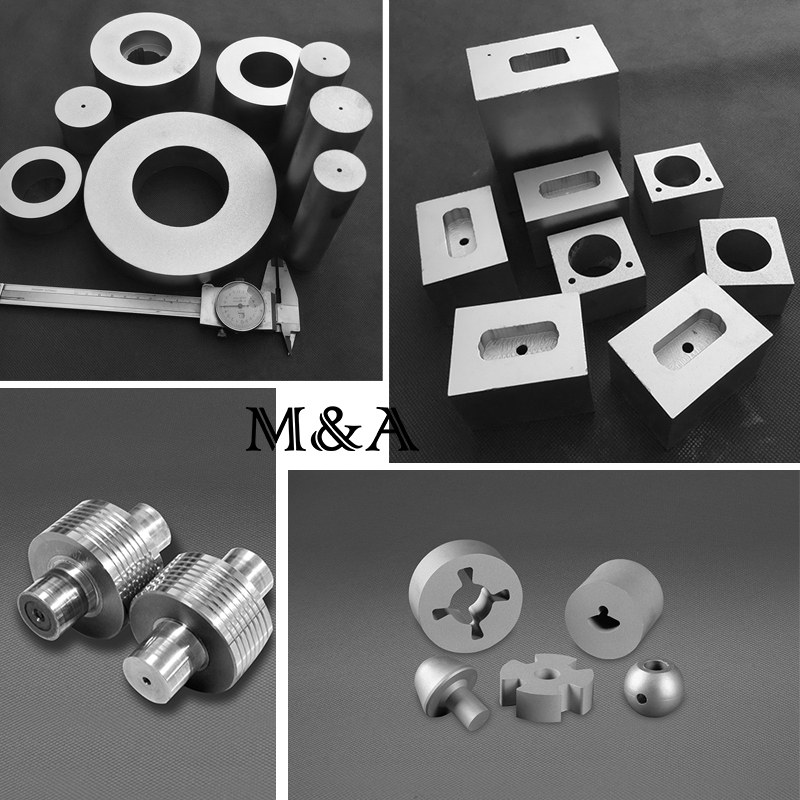

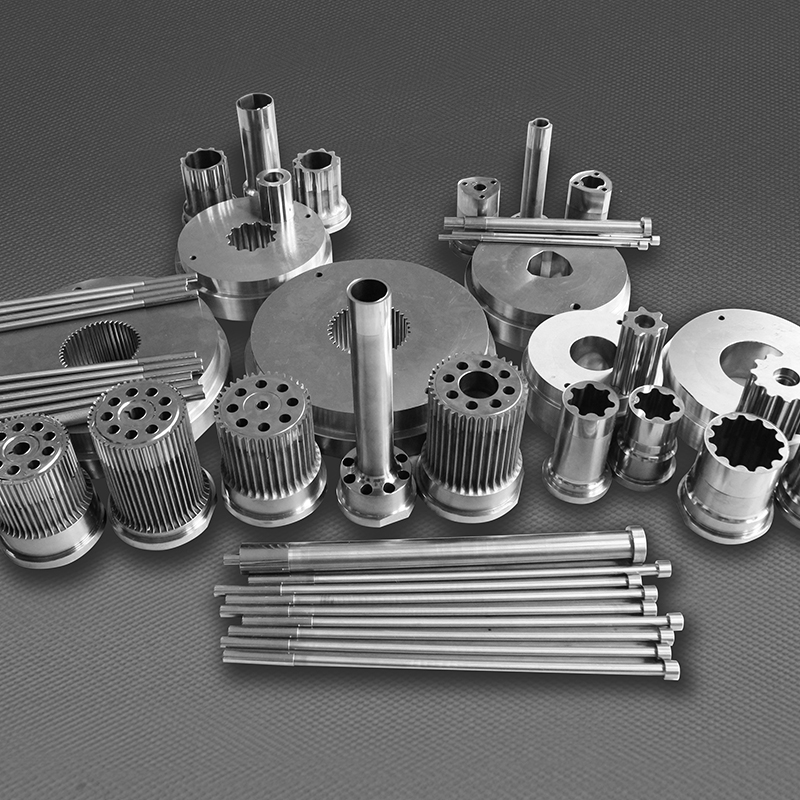

Powder Mold Metallurgy Compacting Dies Tooling

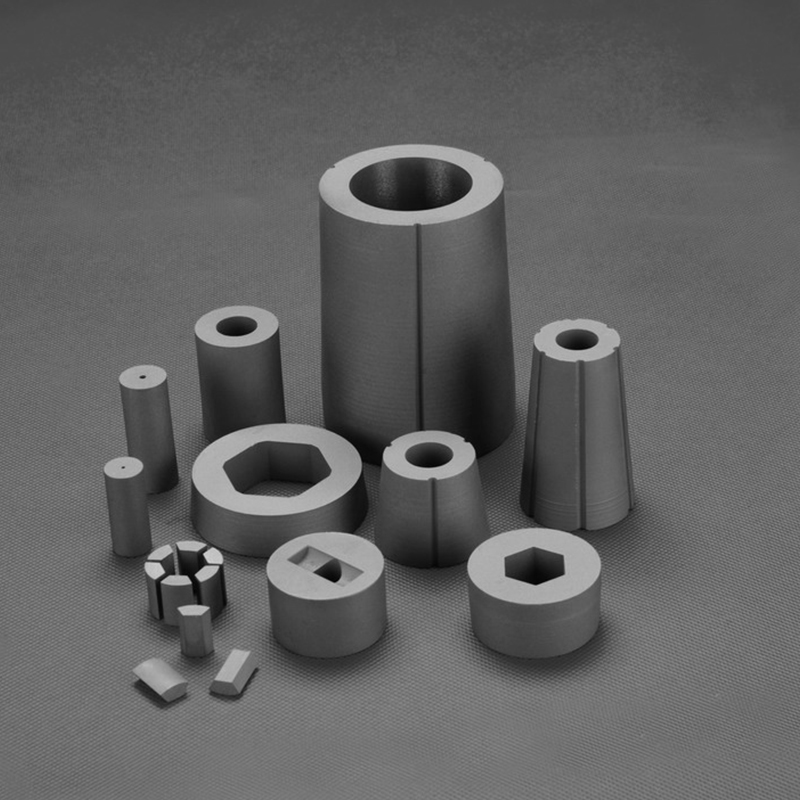

Colding Heading Dies Tungsten Carbide Molds

Cemented Tungsten Carbide Strips Bar

Tungsten Carbide Block Plate Strips

Tungsten Carbide Precision Rolls

Wear-Resistant Mold Blanks

Tungsten Carbide Punches Plates Cemented Sheet