Products

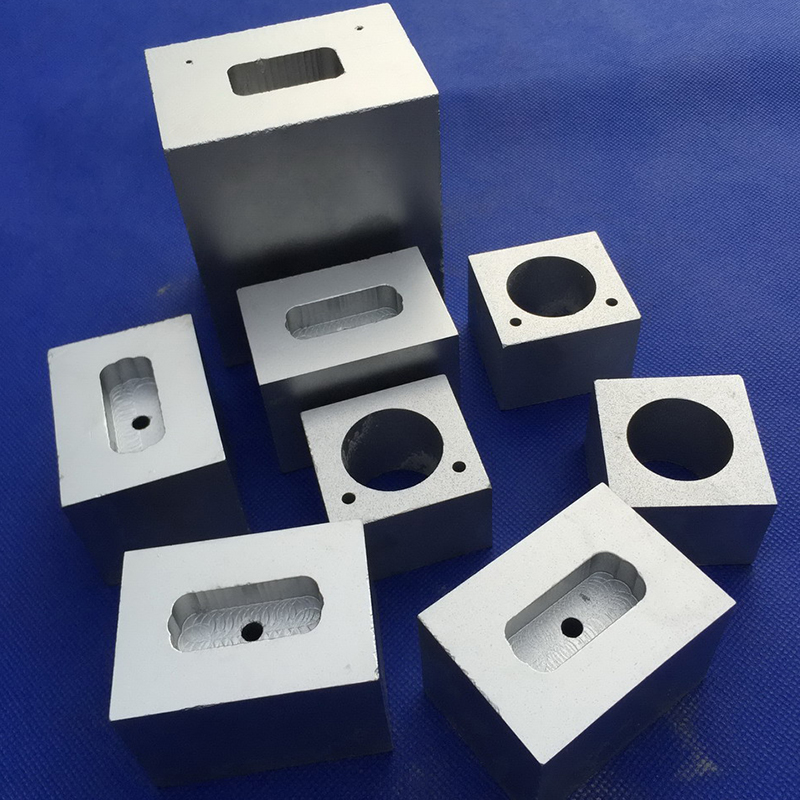

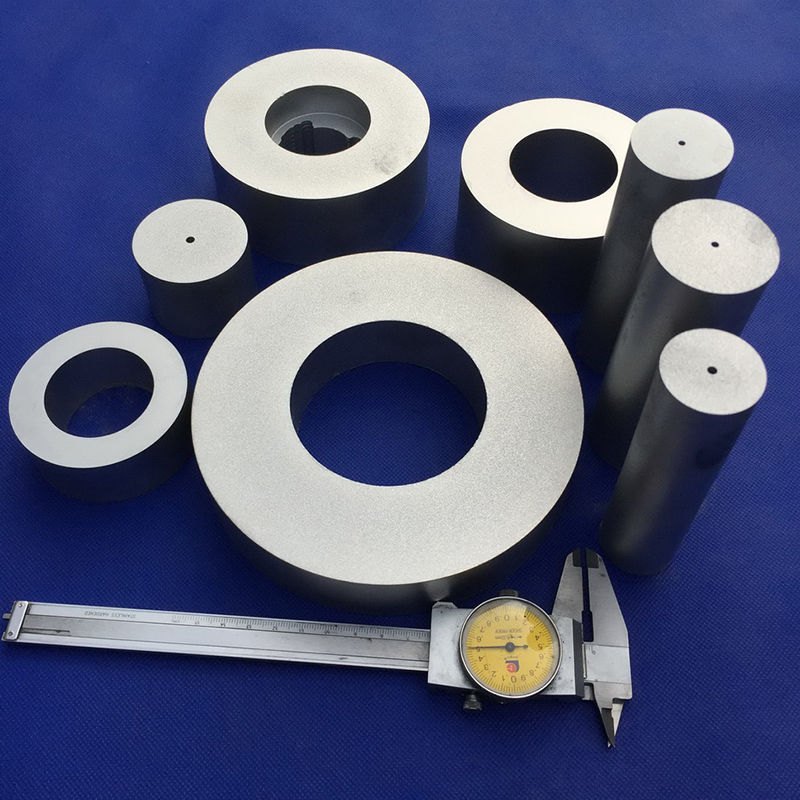

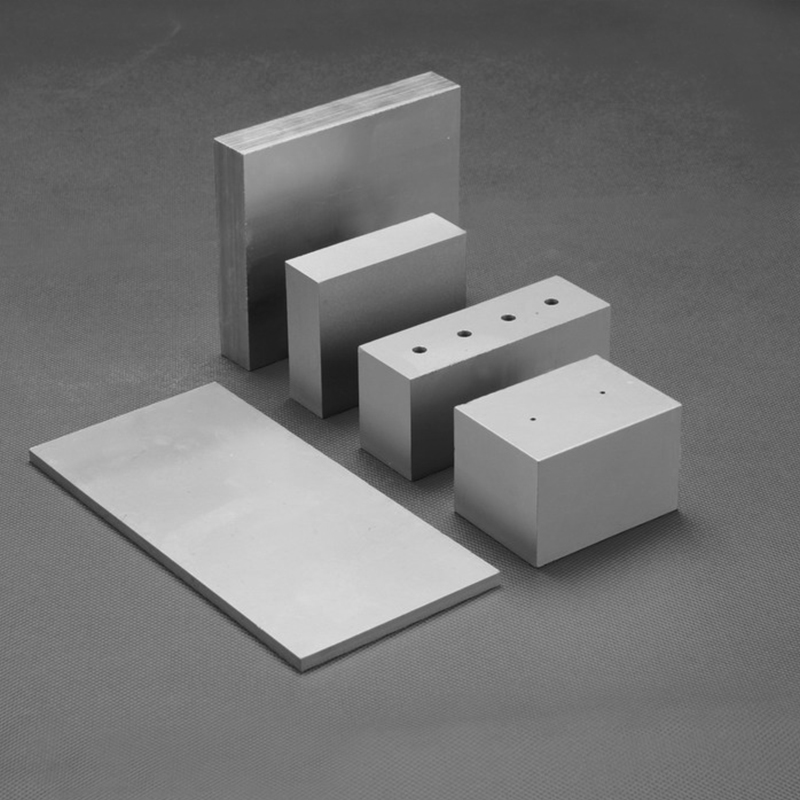

Wear-Resistant Mold Blanks

Five Advantages Of Products

- wear resistant blanks

- powder mold blanks

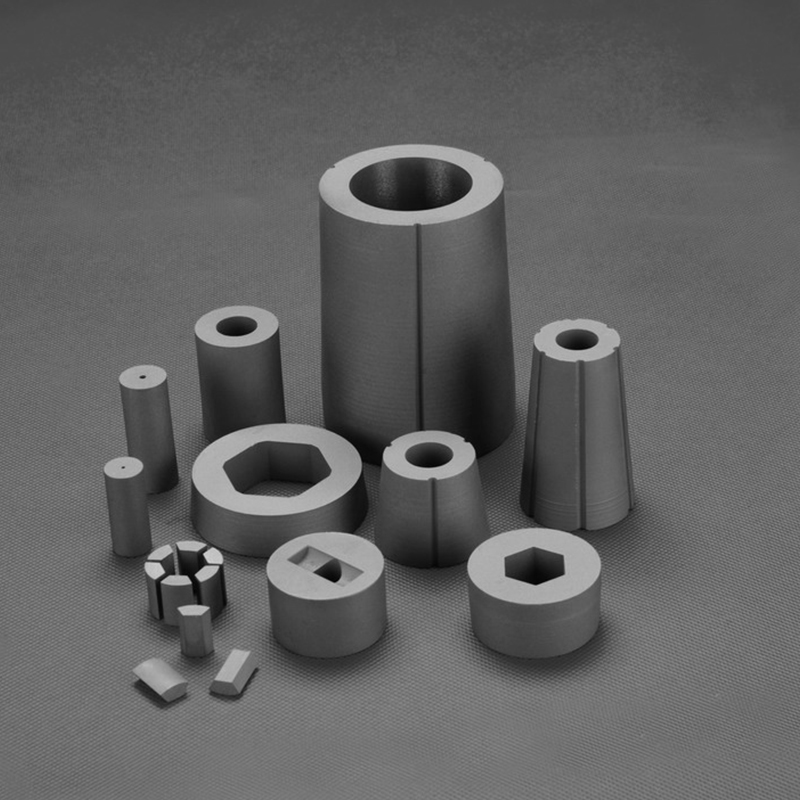

- tungsten carbide cemented mould

- Tungsten carbide metal powder

- tungsten carbide tools

Product Details

Descriptions Of Tungsten

Tungsten also referred to as Wolfram, is a chemical element with the chemical symbol W and atomic number 74. After Carbon, Tungsten has the highest melting point of all elements. Tungsten is among the heaviest metals found on Earth. It has excellent high-temperature mechanical properties, with the lowest expansion coefficient and highest conductivity of all metals.

MiXiao Metal & Alloy is a leading supplier of Tungsten products. We offer competitive pricing and great lead times on all our materials, and we're capable of supplying custom materials per any specs/drawings you provide us with.

Tungsten Mold Wear-Resistant Blanks

Advantage

1.We are a professional tungsten carbide manufacturer in kunshan City over 10 years and have a few senior engineers who specializes in tungsten carbide field for many decades;

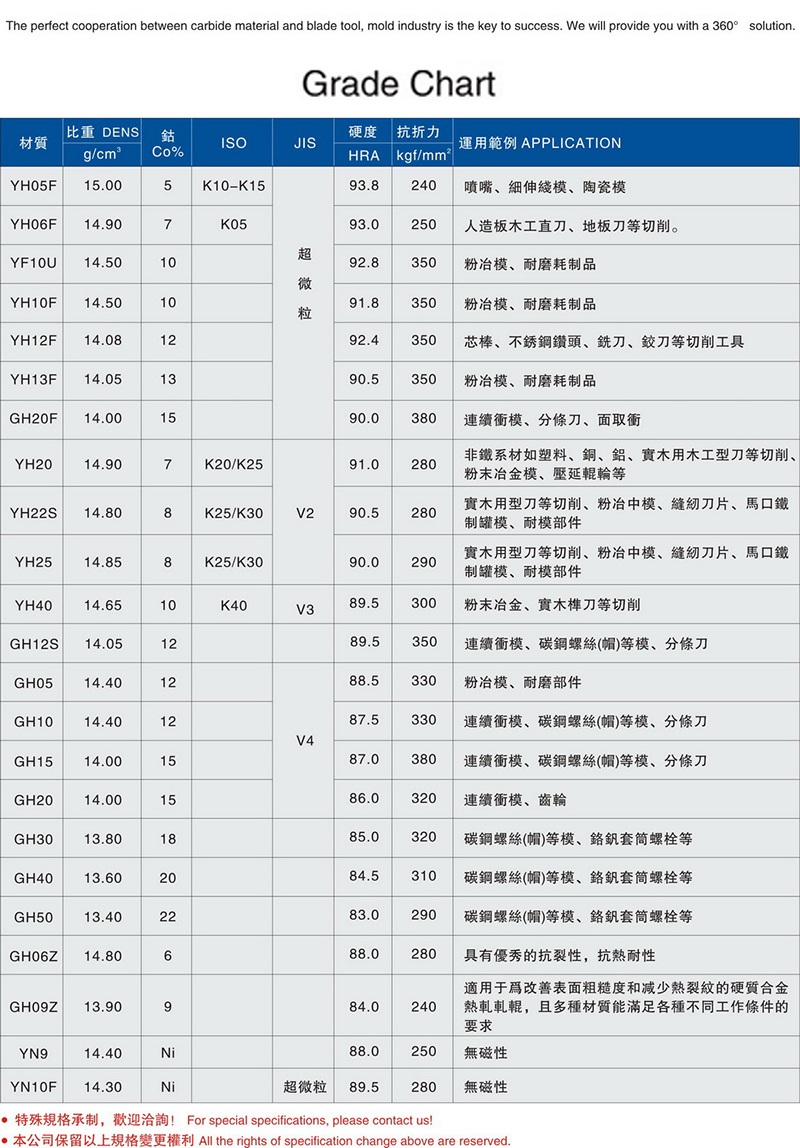

2.Recommended grade :YG6(K10) YG6X YG8(K20) YG15(K30), we can research and developmore suitable formula according to use condition and processing characteristics for client.

3.For your non-standard parts,we have strong ability to make mold by ourselves,and produce them per your requirements.

4.We have strict quality control and assurance system to guarantee the consistent quality.

5.Tungsten has many excellent properties such as high melting point and low vapor pressure, so it is widely used in industrial fields.

6. Useful for glass-to-metal seals since the thermal expansion is about the same as borosilicate glass

7. Tungsten and its alloys are used extensively for filaments for electric lamps, electron, and television tubes, and for metal evaporation work

8. Electrical contact points for car distributors

9. X-ray targets

10. Windings and heating elements for electrical furnaces

11. Missile and high-temperature applications

12. High-speed tool steels and many other alloys contain tungsten

---------------------------------------------

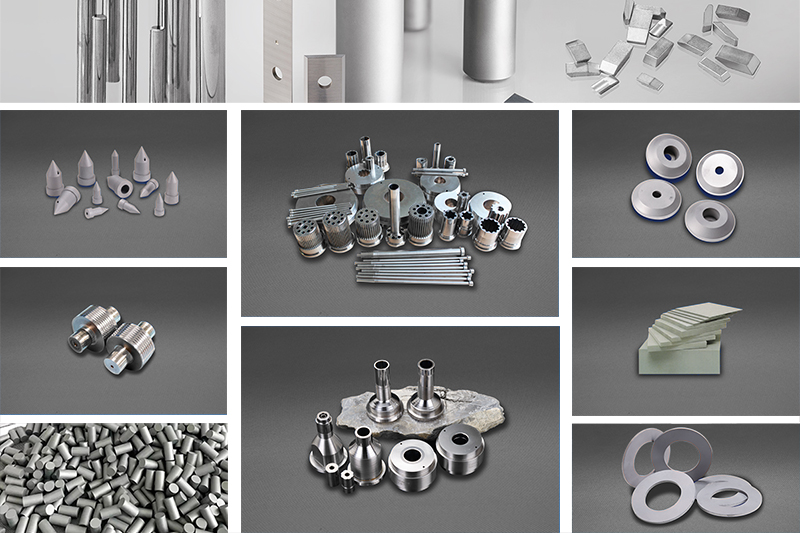

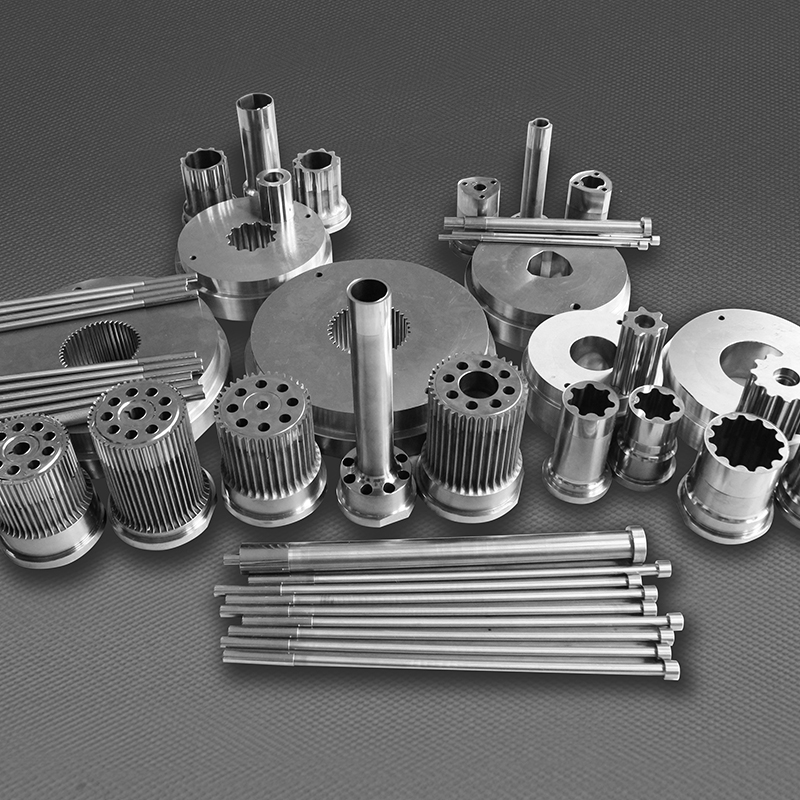

Powder Metallurgy Die Tooling, Powder compaction tooling

Sintered parts for the automotive industry.

Die tooling for oil pump parts, timing belt pulleys, clutch parts, ABS parts, door/trunk interlock parts, power steering parts, sunroof parts, synchro parts etc.

Sintered parts for household appliances and OA equipment.

Die tooling for exterior air-conditioner unit compressors, hard disk parts, small precision motor bearing parts etc.

Sintered parts are precision parts manufactured by press molding fine metal powder in a precision die (powder metallurgy die), which is then hardened by heating (sintering).

Popular for their high material yield rate and high precision, sintered parts are an essential part of the automotive and electrical appliance industries, making it possible to produce complex shapes and mass produce lightweight products.

In the PM process the following three steps are followed in sequence: mixing (or blending), compacting, and sintering.

Mixing: A homogeneous mixture of elemental metal powders or alloy powders is prepared. Depending upon the need, powders of other alloys or lubricants may be added.

Compacting: A controlled amount of the mixed powder is introduced into a precision die and then it is pressed or compacted at a pressure in the range 100 MPa to 1000 MPa. The compacting pressure required depends on the characteristics and shape of the particles, the method of mixing, and on the lubricant used. This is generally done at room temperature. In doing so, the loose powder is consolidated and densified into a shaped model. The model is generally called “green compact.” As is comes out of the die, the compact has the size and shape of the finished product. The strength of the compact is just sufficient for in – process handling and transportation to the sintering furnace.

---------------------------------------------

MiXiao Tech

Contact Person: Michelle

Telephone: +86 13650157503

Landline: +86 13650157503

Company Address: Chang’.an Town,Dongguan City,Guangdong Province,China

Factory Address: Jinxia Industrial Zone,Chang’an Town,Dongguan City,Guangdong Province,China

Website: mixiao.us764.com

Previous: YCUT-F YCUT-M YCUT-FX Titanium Co...

Powder Mold Metallurgy Compacting Dies Tooling

Colding Heading Dies Tungsten Carbide Molds

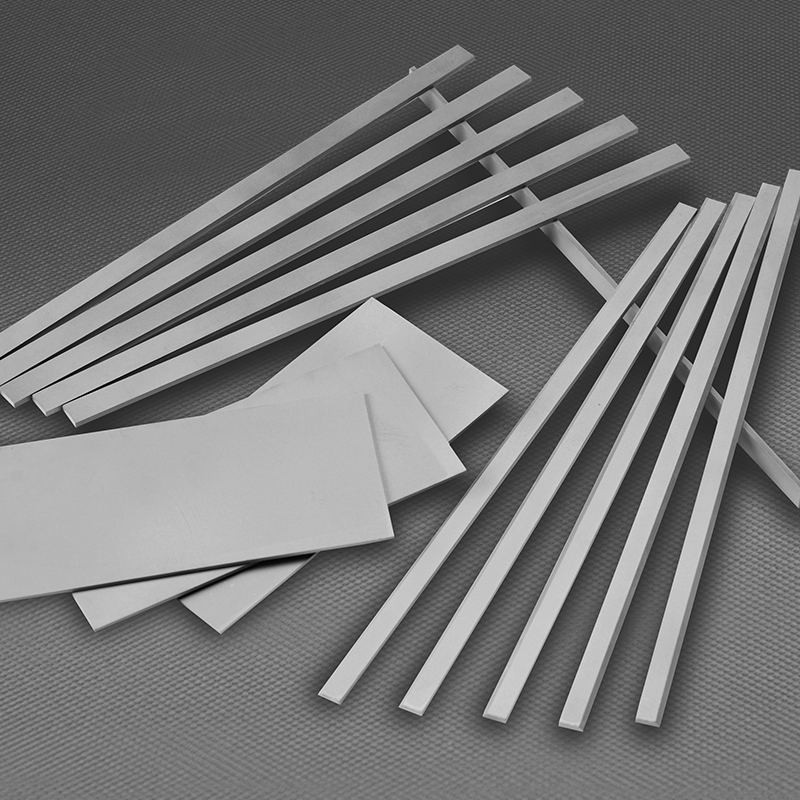

Cemented Tungsten Carbide Strips Bar

Tungsten Carbide Block Plate Strips

Tungsten Carbide Precision Rolls

Wear-Resistant Mold Blanks

Tungsten Carbide Punches Plates Cemented Sheet