Powder metallurgy (PM) is a term covering a wide range of ways in which materials or components are made from metal powders. PM processes can reduce or eliminate the need for subtractive processes in manufacturing, lowering material losses and reducing the cost of the final product.

Powder metallurgy is also used to make unique materials impossible to get from melting or forming in other ways. A very important product of this type is tungsten carbide (WC). WC is used to cut and form other metals and is made from WC particles bonded with cobalt. It is very widely used in industry for tools of many types and globally ~50,000 tonnes/year (t/y) is made by PM. Other products include sintered filters, porous oil-impregnated bearings, electrical contacts and diamond tools.

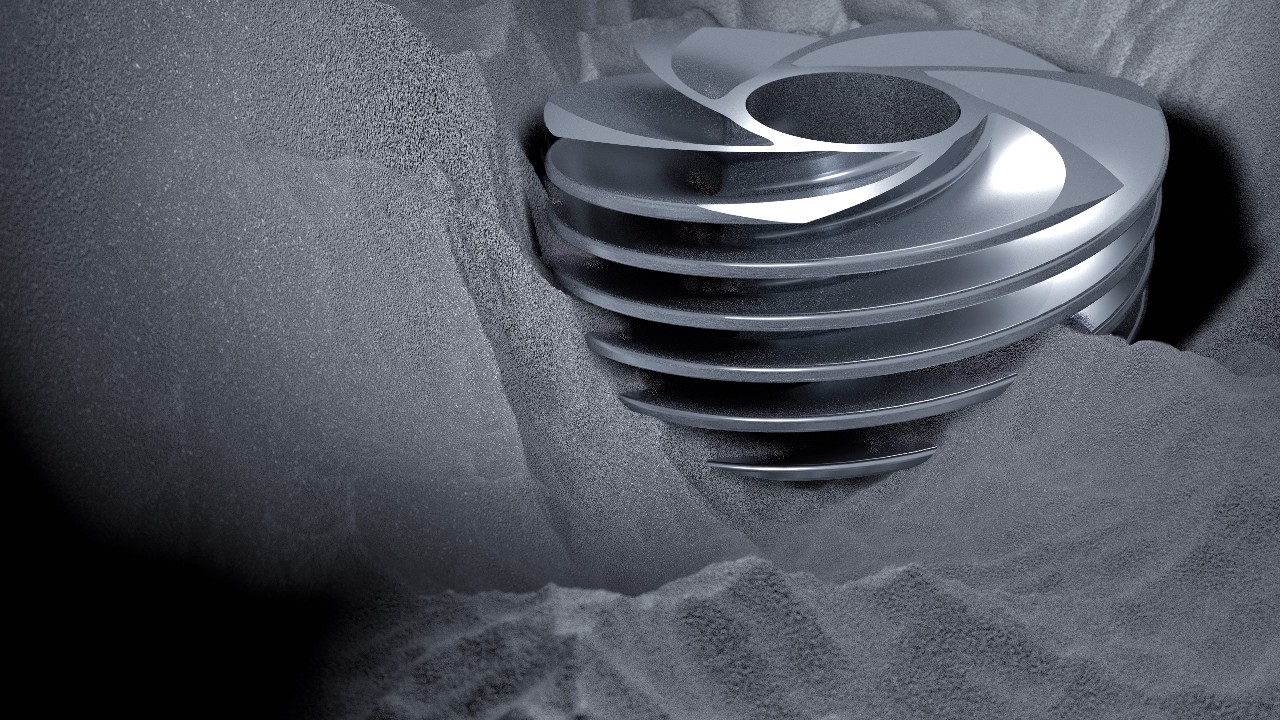

Since the advent of industrial production–scale metal powder–based additive manufacturing (AM) in the 2010s, selective laser sintering and other metal AM processes are a new category of commercially important powder metallurgy applications.

The powder metallurgy press and sinter process generally consists of three basic steps: powder blending (pulverisation), die compaction, and sintering. Compaction is generally performed at room temperature, and the elevated-temperature process of sintering is usually conducted at atmospheric pressure and under carefully controlled atmosphere composition. Optional secondary processing such as coining or heat treatment often follows to obtain special properties or enhanced precision.

One of the older such methods, and still one used to make around 1 Mt/y of structural components of iron-based alloys, is the process of blending fine (<180 microns) metal (normally iron) powders with additives such as a lubricant wax, carbon, copper, and/or nickel, pressing them into a die of the desired shape, and then heating the compressed material ("green part") in a controlled atmosphere to bond the material by sintering. This produces precise parts, normally very close to the die dimensions, but with 5–15% porosity, and thus sub-wrought steel properties. There are several other PM processes which have been developed over the last fifty years. These include:

Powder forging: A "preform" made by the conventional "press and sinter" method is heated and then hot forged to full density, resulting in practically as-wrought properties.

Hot isostatic pressing (HIP): Here the powder (normally gas atomized, spherical type) is filled into a mould, normally consisting of a metallic "can" of suitable shape. The can is vibrated, then evacuated and sealed. It is then placed in a hot isostatic press, where it is heated to a homologous temperature of around 0.7, and subjected to an external gas pressure of ~100 MPa (1000 bar, 15,000 psi) for several hours. This results in a shaped part of full density with as-wrought or better, properties. HIP was invented in the 1950-60s and entered tonnage production in the 1970-80s. In 2015, it was used to produce ~25,000 t/y of stainless and tool steels, as well as important parts of superalloys for jet engines.

Metal injection moulding (MIM): Here the powder, normally very fine (<25 microns) and spherical, is mixed with plastic or wax binder to near the maximum solid loading, typically around 65vol%, and injection moulded to form a "green" part of complex geometry. This part is then heated or otherwise treated to remove the binder (debinding) to give a "brown" part. This part is then sintered, and shrinks by ~18% to give a complex and 95–99% dense finished part (surface roughness ~3 microns). Invented in the 1970s, production has increased since 2000 with an estimated global volume in 2014 of 12,000 t worth €1265 million.

Electric current assisted sintering (ECAS) technologies rely on electric currents to densify powders, with the advantage of reducing production time dramatically (from 15 minutes of the slowest ECAS to a few microseconds of the fastest), not requiring a long furnace heat and allowing near theoretical densities but with the drawback of simple shapes. Powders employed in ECAS can avoid binders thanks to the possibility of direct sintering, without the need of pre-pressing and a green compact. Molds are designed for the final part shape since the powders densify while filling the cavity under an applied pressure thus avoiding the problem of shape variations caused by non isotropic sintering and distortions caused by gravity at high temperatures. The most common of these technologies is hot pressing, which has been under use for the production of the diamond tools employed in the construction industry. Spark plasma sintering and electro sinter forging are two modern, industrial commercial ECAS technologies.

Additive manufacturing (AM) is a relatively novel family of techniques which use metal powders (among other materials, such as plastics) to make parts by laser sintering or melting. This is a process under rapid development as of 2015, and whether to classify it as a PM process is perhaps uncertain at this stage. Processes include 3D printing, selective laser sintering (SLS), selective laser melting (SLM), and electron beam melting (EBM).