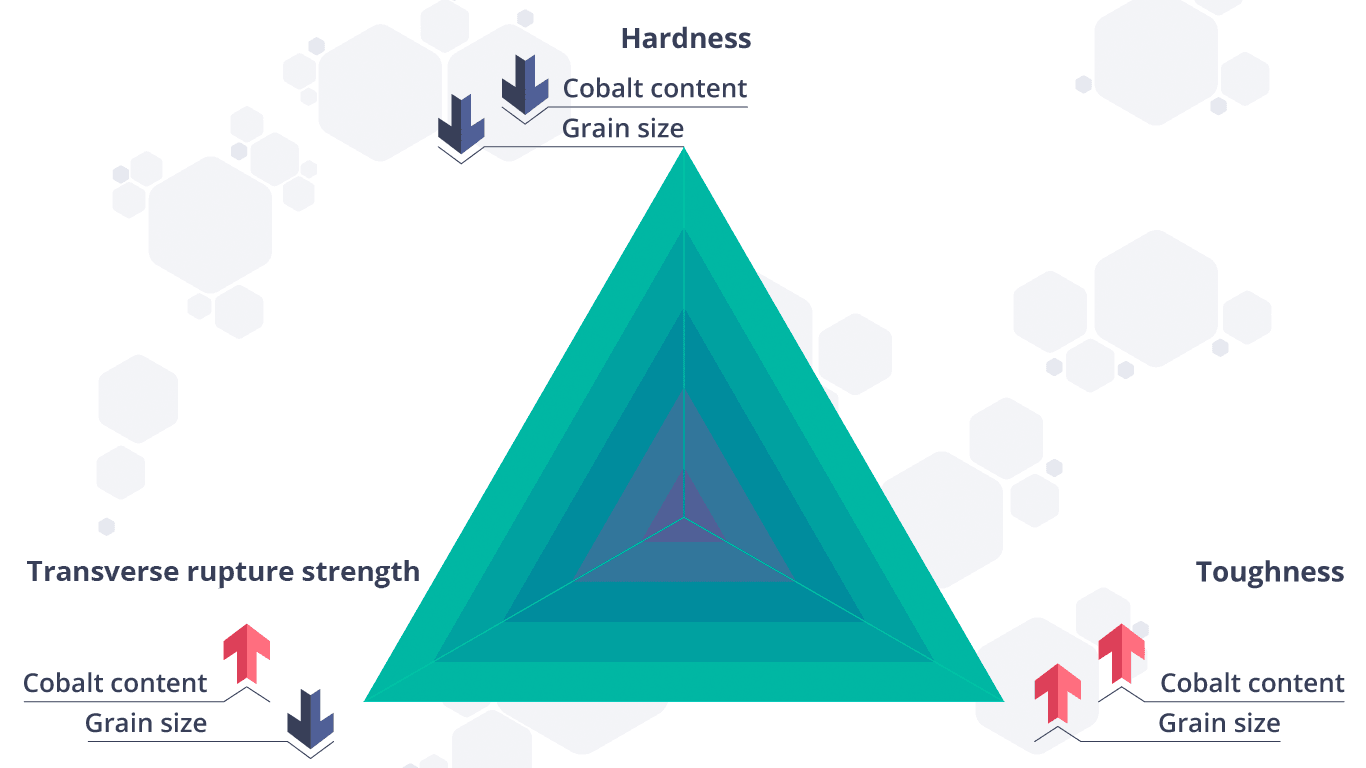

Between hardness, transverse rupture strength and toughness

When selecting a suitable carbide grade for different applications, one moves between the three characteristic poles of hardness (=wear resistance), transverse rupture strength, and toughness, the respective characteristics of which must be balanced depending on the application. However, let us look at three extreme examples to illustrate this:

If the highest possible transverse rupture strength is required, carbide grades with an average cobalt content and a small average grain size are used. An extreme example are drills for printed circuit boards, some of which are thinner than a human hair and are exposed to high bending forces during drilling. In order to resist these forces, a grade with a 9 % cobalt content and a WC grain size of 0.2 µm is used for such drills.

In contrast, maximum wear resistance (hardness) is required in the case of water jet nozzles. They do not have to withstand impact and bending loads but must be as hard as possible to withstand the forces of water and abrasives for as long as possible. To achieve this, carbide grades with minimal cobalt content and small grain size are used. In extreme cases, this is just 0.1 % cobalt and an average grain size of 0.1 µm.

The third extreme case are grades designed for maximum fracture toughness, which are required, for example, for forging hammers. They process the workpiece with high force and must withstand a constant impact load without cracking. With regard to the composition of the hard metal, this means a cobalt content of up to 30 % with a grain size of 10 µm.

Main applications of tungsten carbide

Tungsten carbide is used wherever extreme conditions prevail under which other materials fail. High pressure, high temperature, the use of abrasive or aggressive materials and the machining of hard materials are just a few examples of wear-causing criteria that hard materials and hard metals must withstand.

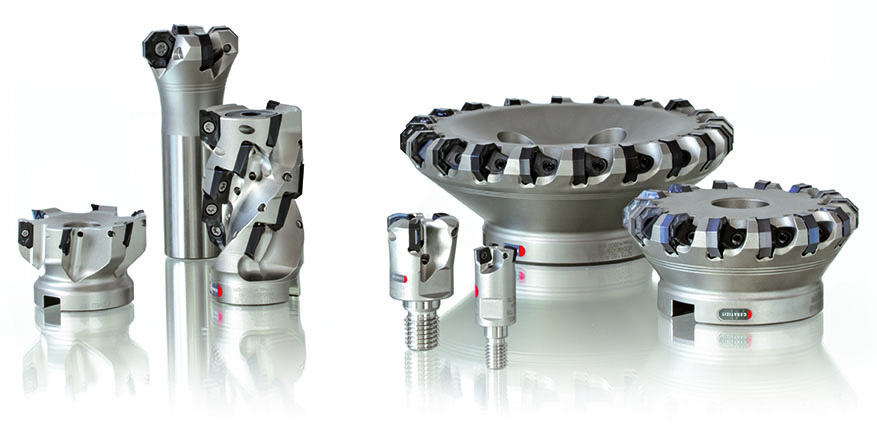

Cutting tools

By far the most important application area for tungsten carbide is metal cutting. The main applications are milling, turning and bore machining, which account for around two thirds of worldwide sales of tungsten carbide. These include both indexable insert tools, in which coated carbide inserts are usually mounted on a steel body, and solid carbide tools.

Tungsten carbide plays an outstanding role in the machining process because it offers a considerably higher wear resistance than high-speed steel (HSS), can withstand higher working temperatures and can be very well optimized to meet the requirements of various processes. At the same time, it is significantly less expensive than tools with polycrystalline diamond (PCD) coating, for example.

At the cutting edge, carbide tools can withstand temperatures of up to 1,100°C with minimal creep, allowing higher cutting speeds and feed rates. In combination with modern CVD and PVD coatings, with which most tools are equipped, carbide tools are also excellently suited for current trends such as minimum quantity lubrication (MQL) and high-speed cutting (HSC), which place even higher demands on the performance of cutting tools.

High-precision tools made of tungsten carbide are used wherever high cutting volumes and maximum precision are required or when tools have to meet special requirements. This is the case, for example, in machine and tool construction, the automotive industry and in the aerospace industry. Especially in the aerospace industry, materials that are difficult to machine and stacks of different materials pose special challenges for tools. Materials that are difficult to machine, such as titanium alloys, also play an important role in the medical industry - both in dental and medical technology - as well as in the energy industry.

Wear parts

In addition to machining, there is, roughly speaking, the wide range of wear protection products that include a large number of very different components for all kinds of industries. In wood and stone processing, for example, carbide is used in the form of saw teeth for circular saws and drill bits for reinforced concrete drills.

In the automotive sector, low-wear components for common rail systems are made of tungsten carbide. In the oil and gas industry, on the other hand, low-wear carbide components minimize downtimes in pipelines and in drilling for exploration. But scratch-resistant watchcases, parts for metal forming and toolmaking, water jet nozzles, sputter targets for the production of diamond-like carbon (DLC) coatings, high-pressure tools for the production of artificial diamonds or blanks for hobs and cutting rolls are also made of tungsten carbide today, to name a few examples.

Special grades approved by the US Food and Drug Administration are even used in medical technology and the food industry. The variety of applications is ultimately only limited by imagination.

For over 95 years, CERATIZIT has been a pioneer developing exceptional hard material products for cutting tools and wear protection. The CERATIZIT Group is the market leader in several wear part application areas, and successfully develops new types of carbide, cermet and ceramic grades.